4 Standard Shipping Container Types & Dimensions: Top Guide

4 Standard Shipping Container Types & Dimensions: Top Guide Global trade requires reliable means to transport goods across vast distances, and these means come in the form of shipping containers. From everyday consumer products to heavy industrial equipment, standard shipping containers are designed to carry a wide range of cargo across various industries. The design is not deliberate, though. The dimensions are consistent, depending on the container type, to aid the logistics and to simplify their handling during long trips, as well as in storages.

If you are involved in shipping or logistics, you will benefit from understanding the types of standard containers, such as 20ft or 40ft, and their special derivatives like high cube. We shall break down different container types, their dimensions, and their common uses to help you make weighted decisions, whether you’re shipping goods, managing inventory, or considering a container for a non-traditional use.

What is a standard shipping container?

A standard shipping container is a large metal box (although not a crate, for it is another terminology, different from a container) designed for transport of cargo by sea, land, or rail. Following globally accepted specifications, it is easy to handle, stack, and move between locations.

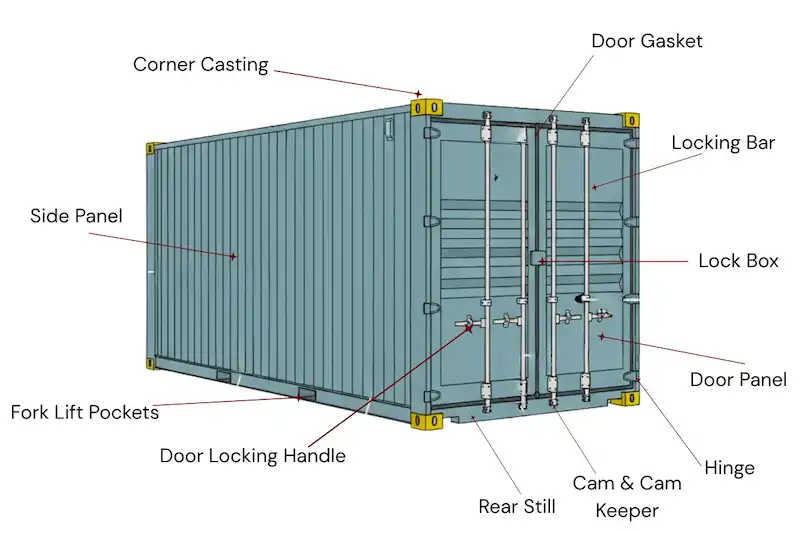

Containers are built to withstand long journeys and harsh conditions, with weather-resistant exteriors and reinforced corners for secure stacking. Their structure and size make them suitable for nearly all types of shipping: heavy machinery, personal goods, etc.

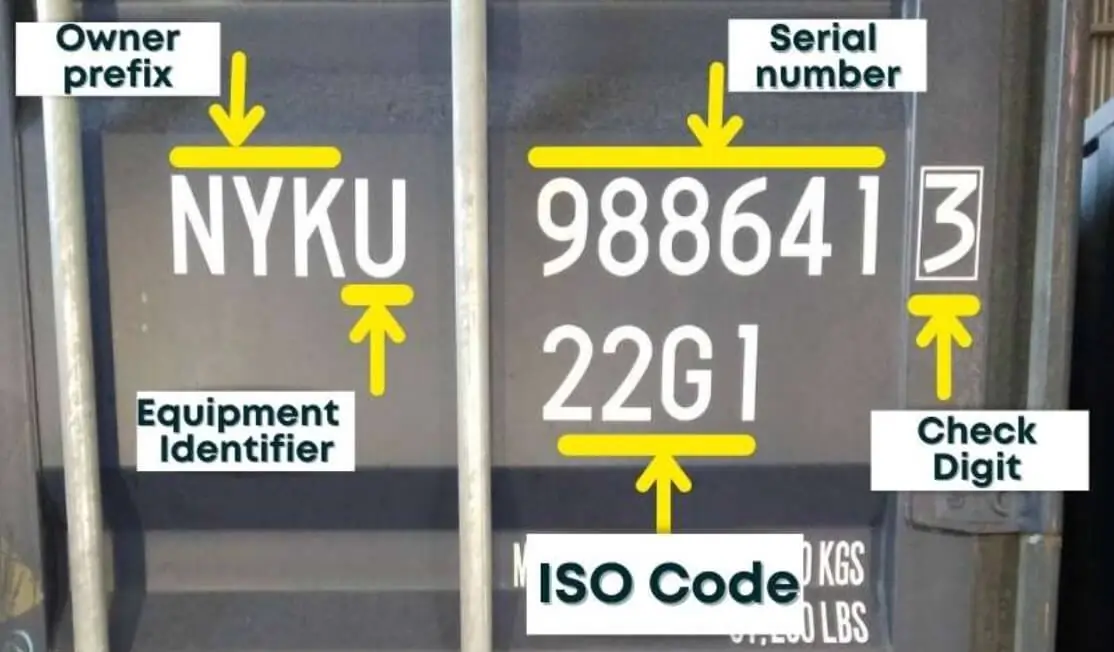

Containers vary, but standard units are typically rectangular and made of corrosion-resistant steel. Each has specific dimensions, weight limits, and capacity, governed by ISO standards to maintain compatibility across global shipping networks. The uniform design of these containers is central to the efficiency of global trade, allowing for predictable handling with cranes, forklifts, and specialized vehicles. Proper maintenance prolongs their lifespan to 15 years, which contributes to long-term logistics planning.

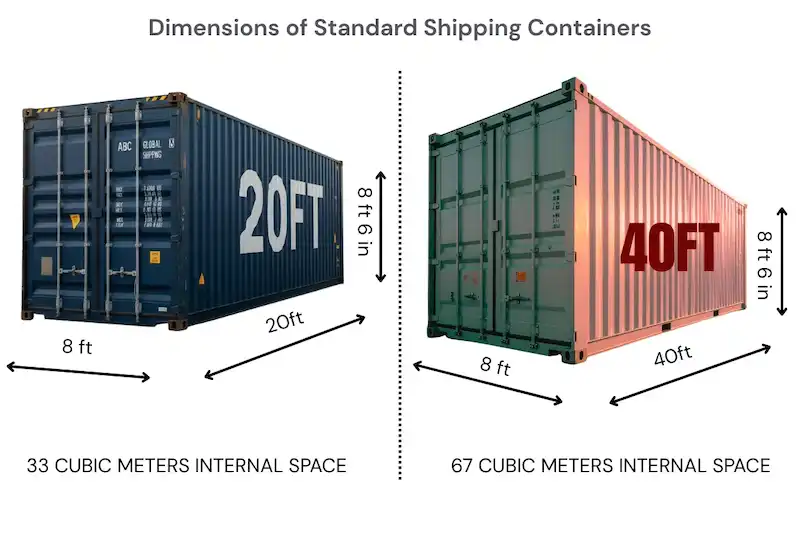

Dimensions of standard shipping containers

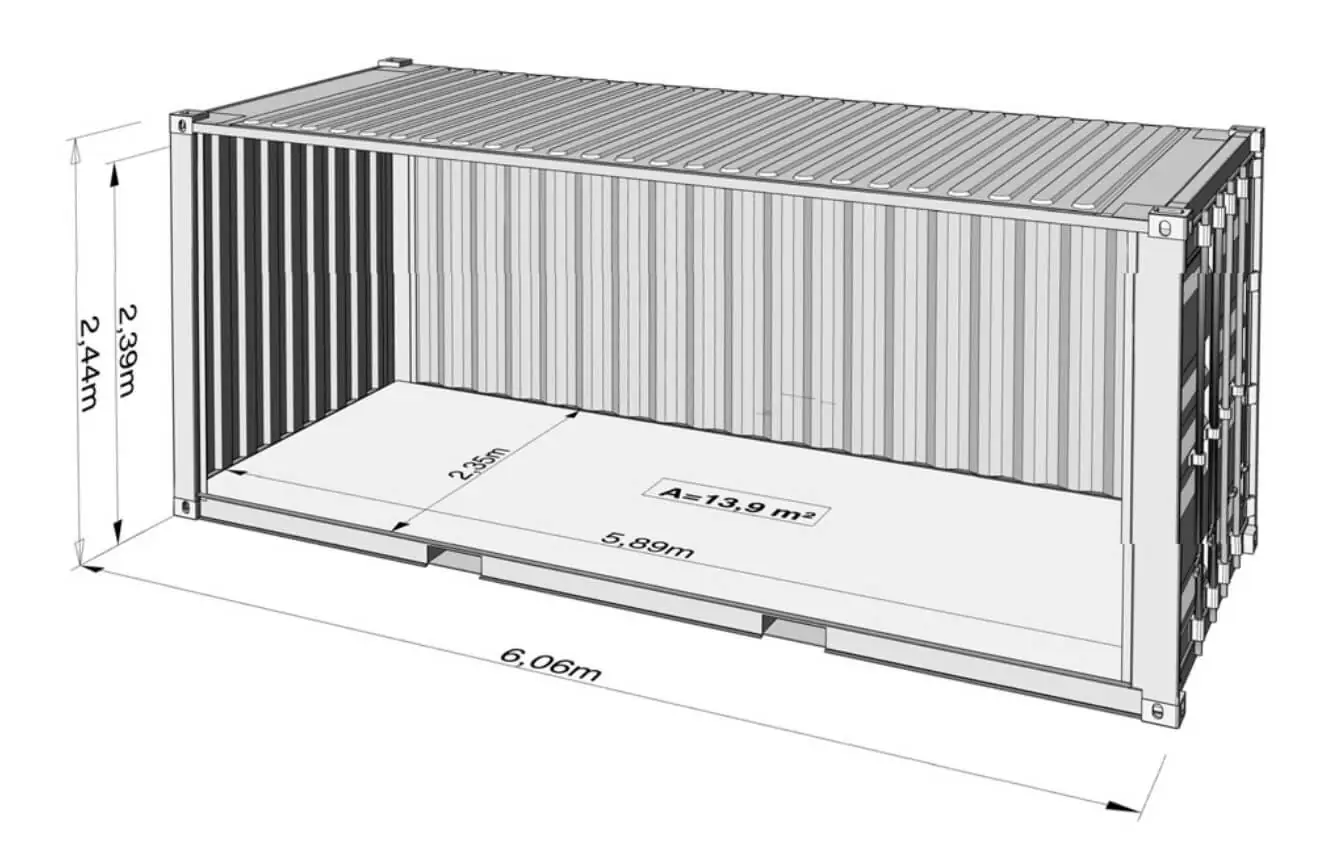

Most shipping containers come in two sizes: 20‑foot and 40‑foot. The 20‑footer is about 20 feet long, 8 feet wide, and 8 feet 6 inches tall on the outside, providing roughly 33 cubic meters of space internally (this may vary slightly depending on the walls and doors). The 40‑footer, while having the same width and height, doubles that length, which expands the internal space to about 67 cubic meters. The internal length of a 40ft container is typically about 5.9 meters.

The 40ft variant is ideal for large shipments due to its increased capacity. The internal width is generally 7 feet 8 inches, while the door opening matches this width, thanks to which forklifts and palletized cargo pass through easily. The internal height is 7 feet 10 inches, which accommodates most goods, including taller or irregular items when packed efficiently. Most container floors are constructed with marine-grade plywood over steel cross members, which adds structural strength and durability.

The weight limits may vary but the empty 20-foot container typically weighs about 2,300 kg, while the 40-foot version weighs around 3,750 kg. The maximum gross weight of a 20-foot container is generally about 30,480 kg, while the 40-foot model can handle up to 32,500 kg. These weight limits are standardized for easier management of load distribution, as overloading will threaten structural integrity of both the container and the transport vehicle.

Main types of standard shipping containers

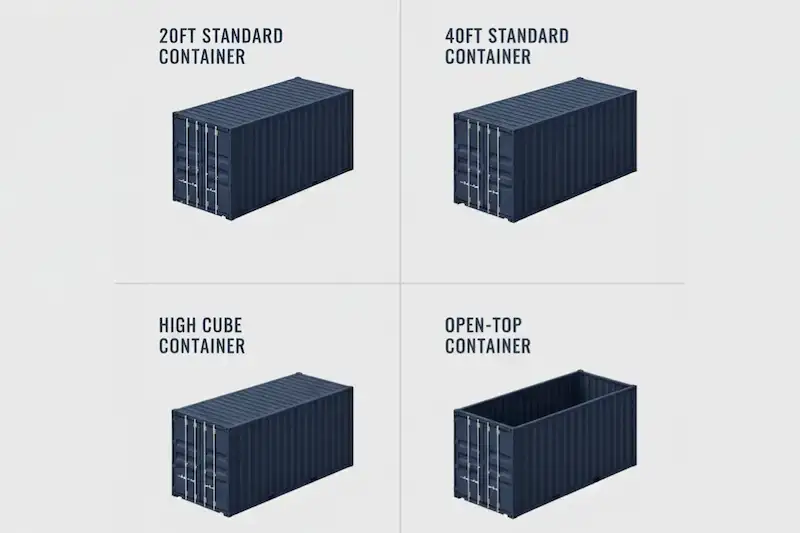

We can distinguish four main types of standard shipping containers:

- 20ft. Compact and widely used, the 20-foot container suits smaller loads or weight-dense cargo. Its size makes it practical for tighter spaces or frequent relocations. Modular setups like site storage or mobile work units make good use of these.

- 40ft. This type offers more room without changing the width or height. It fits larger or palletized cargo and is often used for bulk transport to warehouses or distribution points. The added length allows better space use for non-fragile goods.

- High cube. With an extra foot of height, the high cube handles taller stacks or bulky, lightweight goods. It supports double-stacking or elevated shelving and is often chosen for materials that don’t fit standard-height units.

- Special containers. These include reefers, flat racks, open tops, and other purpose-built types. Though made for specific loads, they keep standard external dimensions. They’re used when typical containers don’t meet space, shape, or cargo condition requirements.

The distinct measurements, capacities, and structural features make each type designed for varied loading and shipping needs. For example, some containers may include modifications like additional doors, side openings, or roof access to enhance accessibility for specific cargo types or the location specificity.

While some containers serve general transport needs, others, like reefers, maintain controlled environments for perishable goods, such as food and pharmaceuticals. These specialized containers integrate insulation and cooling units, which affect their internal dimensions and total usable space. Yet they still fall within a standard footprint for location and stacking compatibility, allowing them to be loaded and arranged alongside regular units.

The modular structure of standard containers allows for flexible use across industries, including manufacturing, construction, mining, retail logistics, and humanitarian aid. Here’s why those numbers matter: overloading or loading cargo unevenly can make boxes slide around, or worse, you risk damaging the container walls. This is especially important when transporting either fragile or high-density materials. Moreover, container specifications also may require alignment with cranes or forklifts — a factor to consider if you want to ensure maximum safety for the cargo.

20ft standard shipping container

The 20ft standard shipping container is one of the most commonly used types. Ideal for small to medium loads, it supports a capacity of roughly 25,000 kg. With external dimensions of 20’ x 8’ x 8’6”, it’s frequently used for both commercial freight and private moves. Its smaller footprint also makes it suitable for modified applications like portable offices or storage units. This caliber is popular among on-site construction teams due to its ease of placement and maneuverability.

Its relatively light weight and compact size allow easy transport in restricted spaces. This unit is also not impactful on your budget, no matter if you are dealing with bulk goods or boxed cargo. Explore varied options of 20ft shipping containers and find the one that fits your needs.

If you prefer full door access from both ends for better loading/unloading, 20ft standard tunnel double door containers is an awesome choice. This dual-access feature is particularly useful at locations where maneuvering space is limited or where loading sequences require compartmentalized entry. Interior lighting and shelving modifications are also available on many 20ft variants, expanding their usability.

40ft standard shipping container

The 40ft container is another standard in global trade. With its extended length, it offers more room without doubling the weight. Common external dimensions are 40’ x 8’ x 8’6”, while the internal volume accommodates larger or longer cargo, including construction equipment, stacked pallets, or oversized retail stock. Some shippers also retrofit 40ft containers into modular housing or mobile clinics.

Preferred for high-volume or oversized goods, this type offers efficiency in long-haul transport. Despite being larger, it stacks just like a 20ft unit, maintaining consistency at the location of ports or warehouses. Forklift access and standard door dimensions also remain compatible with conventional loading systems.

Many logistics providers choose this format for bulk shipping needs. Those looking to purchase can view the full selection of 40ft shipping containers based on availability and price. Due to economies of scale, 40ft units often provide a better price per cubic meter, particularly for non-fragile cargo that benefits from consolidated space. They also support higher stacking loads in yard storage configurations.

High cube standard shipping container

The high cube variant of the standard container offers an additional foot in height. It’s designed for cargo that requires more vertical space, especially when goods are stacked inside. With an internal height of around 8 feet 10 inches, the external dimensions of a 40ft high cube are typically 40’ x 8’ x 9’6”. The increased height can become a game-changer when transporting tall machinery or light but voluminous goods like textiles or insulation material.

Apart from the taller size, other dimensions like the width, length, and base structure remain the same as other standard types which makes such containers compatible with standard lifting and stacking equipment. This compatibility simplifies integration into existing storage systems and transport lines. The added height makes them useful for double-stacked pallets or items with overhead clearance requirements.

You can browse 40ft high cube containers to see options for added internal capacity. Some cargo types, like automotive parts or vertical shelving systems, benefit directly from the higher clearance.

Other modifications include high cube versions with extra features, such as 20ft high cube double door tunnel containers, which provide both size and access advantages. For more specialized uses, 20ft side opening high cube containers offer easy side loading for difficult cargo, especially when access from the front or back is limited due to location constraints or interior partitioning. Side doors can be full-length or partial, depending on configuration, and allow direct reach with mechanical loaders.

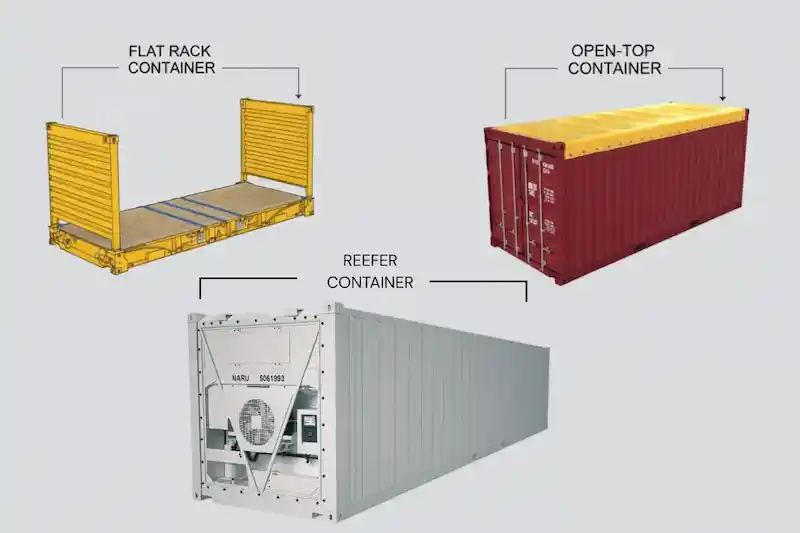

Standard dimensions of special containers

Special containers maintain standard footprints but feature structural differences. These include reefers (refrigerated containers), open-top models, and flat racks. Though designed for specific purposes, they conform to standard stacking and location systems. Their uniform dimensions help maintain compatibility across mixed shipping environments. Some variants also have built-in floor anchors for securing awkward or fragile loads.

Reefers typically follow 20ft or 40ft dimensions and incorporate refrigeration units. Their internal capacity is slightly reduced due to insulation and cooling systems, but they still handle significant weight and volume. Temperature settings can be adjusted between -30°C and +30°C, making them suitable for pharmaceuticals, dairy products, frozen goods, and other sensitive cargo. Monitoring systems and power connections are standardized to integrate with vessel or warehouse supply setups.

Open-top containers work best for oversized cargo, while flat racks handle odd shapes with ease. Without fixed roofs or side walls, these units let cranes lower loads straight in. You’ll often see pipes, heavy machinery and prefabricated sections shipped this way. To shield items from the elements, a simple tarp system usually covers the top.

Some special versions come in high-cube form, offering taller interiors and various door setups. They’re a natural fit for bulky or high-volume loads that demand adaptable handling. You won’t find them at every terminal, but their uniform dimensions make them plug-and-play with standard freight networks. Choosing between open tops, flat racks and other specialty containers comes down to what you’re shipping — its size, shape and weight — and the lifting gear available at both ends.

Conclusion

Standard shipping containers have become an irreplaceable tool for global transport due to their versatility and robust design. Spacious 40ft containers or compact 20ft models fit various purposes, from traditional freight shipping to specialized applications (refrigerated goods, mobile storage units, etc.), although the choice usually depends on the nature of the cargo and the shipment specifications. By properly considering the capacity, weight, and dimensions of each type, you make sure that the goods are transported in the most efficient way.

Vanessa is a dedicated writer and content enthusiast at Pelican Containers. With a background in practical writing and a keen eye for clarity, she transforms complex container topics into easy-to-understand and useful content. Her passion lies in exploring the evolving world of container usage — from smart storage hacks to global logistics trends.

When she's not writing, Vanessa loves discovering creative shipping container projects or traveling to find new inspiration.

Explore thoughtful, informative, and accessible content with Vanessa!

Vanessa is a dedicated writer and content enthusiast at Pelican Containers. With a background in practical writing and a keen eye for clarity, she transforms complex container topics into easy-to-understand and useful content. Her passion lies in exploring the evolving world of container usage — from smart storage hacks to global logistics trends.

When she's not writing, Vanessa loves discovering creative shipping container projects or traveling to find new inspiration.

Explore thoughtful, informative, and accessible content with Vanessa!

FAQ

What is a standardized container?

A standardized container meets ISO criteria for size, strength and handling features so it can travel seamlessly across ships, trucks and trains. Typically steel‑constructed with uniform corners and fittings, these boxes stack neatly in ports and secure safely under varying climates.

What size is a standard shipping container?

A standard shipping container typically comes in two main sizes: 20ft and 40ft. A 20ft container measures 20 feet long, 8 feet wide, and 8 feet 6 inches high, with an internal capacity of around 33 cubic meters. The 40ft container is double the length at 40 feet long and also 8 feet wide and 8 feet 6 inches high, offering an internal capacity of about 67 cubic meters. Both sizes are considered the industry standard and are used for most types of goods. There are also high cube versions, which are 1 foot taller, providing additional internal height for taller or more voluminous cargo.

What is the most common shipping container?

The 20‑foot standard box remains the workhorse of the industry. Measuring 20 by 8 by 8 ½ feet, it strikes the right balance between capacity and manageability. Whether moving factory parts or household goods, its manageable size and widespread availability make it the go-to option. It fits on trucks, trains and ships alike, and slips into tight spots where larger units simply won’t.