Stacking Shipping Containers Safely for Efficient Storage

Shipping containers are everywhere, from bustling ports to storage yards, but stacking them is harder than it seems. It’s all about balance, safety, and making the most of available space. Here are several essential guidelines and tips for stacking these containers properly. Whether you’re new to the logistics industry or just looking for a refresher, explore the best practices to keep these steel boxes safe and efficiently stored.

How Shipping Containers Are Stacked

Stacking shipping containers demands precision, akin to a masterful architectural feat rather than a simple stacking chore. First, it’s significant to understand the container’s corner castings — high-strength, standardized fittings located at all four corners of the container. They allow vertical stacking by aligning and locking with the container below, creating a secure, interlocked bond.

A comprehensive assessment of the base surface is conducted before stacking. The ground must be both level and firm to prevent any potential leaning or instability. Furthermore, soil tests can be conducted in larger yards to ensure the land can bear the weight of multiple stacked containers.

Once the groundwork is ensured, the next step is the visual and structural assessment of the container. This step is important. Any significant dents, deformities, or rust can compromise the container’s structural integrity, posing a risk when stacked.

When the time comes to lift and place the container, specialized machinery is employed. This isn’t a job for a standard forklift. Heavy-duty cranes or straddle carriers, operated by personnel with specific training in container handling, are used. These machines provide the precision for aligning the containers perfectly, ensuring the corner castings interlock securely.

Lastly, the alignment itself is of utmost importance. Even a minor misalignment can lead to increased pressure on one part of the container, potentially leading to deformation or even the collapse of the stack. Therefore, modern yards often use laser-guided systems or computer-assisted alignment tools for extra security.

Stacking Cargo Containers: Which Types Are Stackable

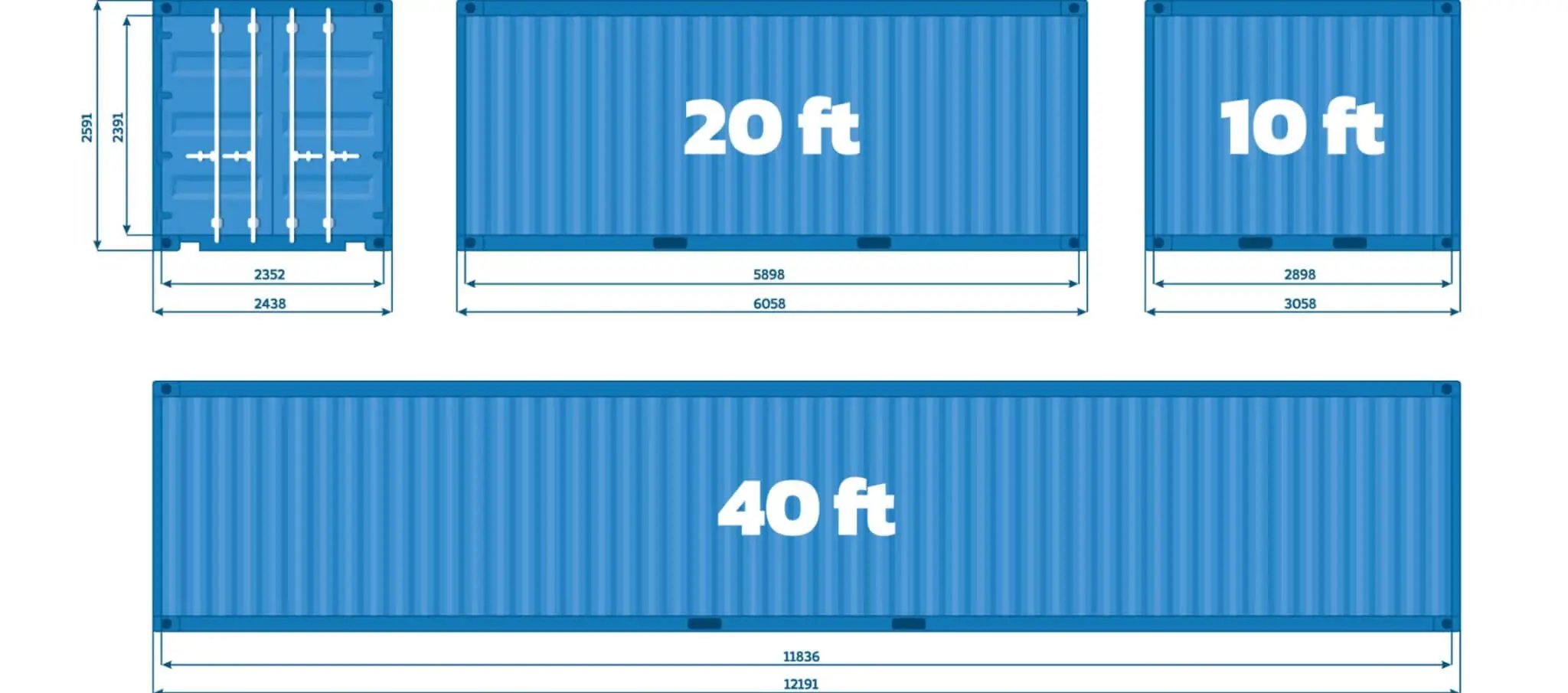

Not all containers are made equal. Although most are stackable, understanding the differences is essential for storage efficiency.

- Dry storage containers. The most common type, used for general cargo. They’re designed for stacking, with their standardized sizes and robust build.

- Refrigerated containers. Equipped with cooling systems, they can also be stacked. However, ensure that the refrigeration units are accessible and operational.

- Tank containers. For transporting liquids, stacking these requires more caution due to the fluid inside, which can shift and pose stability issues.

- Open top and flat-rack containers. Their unconventional designs mean they’re not stacked atop other container types.

It might be tempting to stack shipping containers as high as possible to maximize storage, but there are limits, regardless of the chosen type. Typically, in controlled environments like storage yards, shipping containers can be stacked up to 7‒8 containers high. However, this number can vary depending on factors like container condition, weight distribution, and local regulations to ensure everything is done safely. It’s crucial to prioritize safety over storage maximization.

6 Tips on How to Keep Your Storage Container in Great Condition

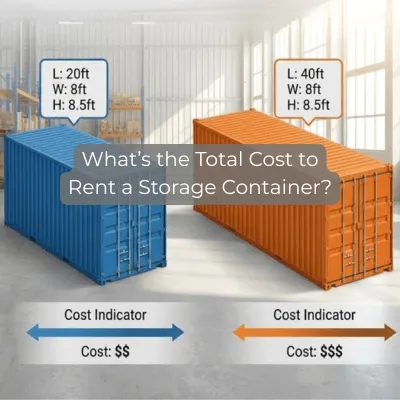

Used shipping containers are a much-preferred storage option. These robust boxes are easy to find and are much cheaper than the construction cost of a typical storage shed of the same dimension.

Vanessa is a dedicated writer and content enthusiast at Pelican Containers. With a background in practical writing and a keen eye for clarity, she transforms complex container topics into easy-to-understand and useful content. Her passion lies in exploring the evolving world of container usage — from smart storage hacks to global logistics trends.

When she's not writing, Vanessa loves discovering creative shipping container projects or traveling to find new inspiration.

Explore thoughtful, informative, and accessible content with Vanessa!

Vanessa is a dedicated writer and content enthusiast at Pelican Containers. With a background in practical writing and a keen eye for clarity, she transforms complex container topics into easy-to-understand and useful content. Her passion lies in exploring the evolving world of container usage — from smart storage hacks to global logistics trends.

When she's not writing, Vanessa loves discovering creative shipping container projects or traveling to find new inspiration.

Explore thoughtful, informative, and accessible content with Vanessa!

FAQ

What are some common safety concerns when stacking shipping containers for storage?

Overloading, misalignment, and unstable ground are primary concerns. Any of these can lead to tipping which poses serious safety risks.

How can container stacking be optimized to maximize storage efficiency?

Ensuring uniformity in container sizes, maintaining a strict inspection routine for container integrity, and utilizing computer-assisted stacking plans can improve efficiency.

What are some important factors to consider when choosing a location for container stacking?

Firm, level ground is essential. Proximity to transportation hubs, accessibility, and good drainage to avoid water pooling are also crucial

How do weather conditions and environmental factors impact container stacking safety?

High winds can destabilize stacks. Extreme temperatures might affect container materials. Therefore, consider local weather patterns and use wind barriers or other protective measures if needed.