Shipping Container Weight: How it Impacts Your Costs

Every pound counts in the shipping industry, and the weight of your shipping container makes all the difference. Even a few kilograms can tip the scales on your shipping costs. In this article, we’ll tell you everything about shipping container weight, explore the three main types of weights you need to know, and learn how container weight impacts your costs.

How Much Does a Shipping Container Weigh?

Well, one of the questions on everyone’s mind is: how much does a shipping container weigh? The answer isn’t as straightforward as you think — the weight varies based on the container’s size and construction materials.

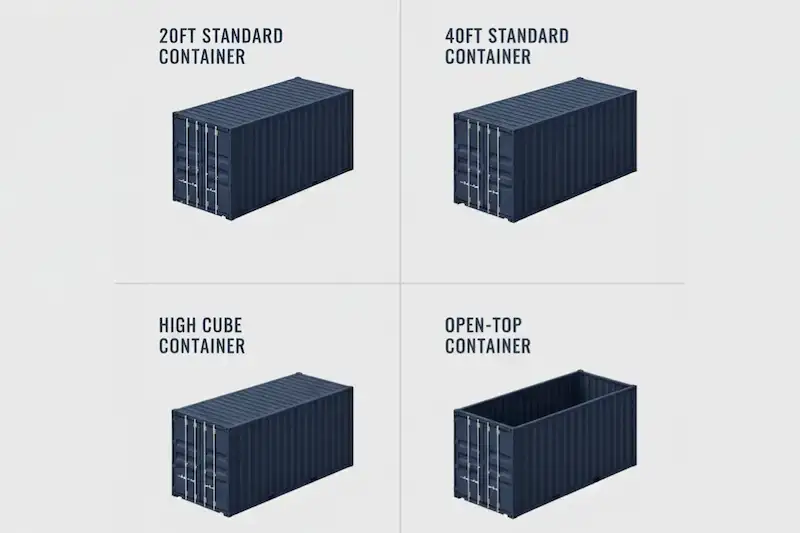

Let’s start with the classic 20ft container. On average, these modest steel boxes weigh approximately 2,080 to 2,400 kg (4,585 to 5,290 lbs) when empty. This is what’s known as the empty shipping container weight. It’s the standard for many shipping operations as it offers a balance between capacity and maneuverability.

Next up, we have the 40ft container, which naturally tips the scales a bit more. The empty 40 ft container weight typically falls between 3,500 to 3,800 kg (7,716 to 8,380 lbs). Its larger frame allows for transporting more hefty loads.

There’s also the 40ft high cube container. This one adds an extra foot of height, which slightly increases its weight. The empty weight of a 40ft high cube container generally ranges from 3,760 to 4,000 kg (8,290 to 8,820 lbs). This means additional space for cargo without a significant increase in weight.

3 Types of Shipping Container Weights

There are three key types of container weights that everyone should know: tare weight, gross weight, and payload capacity.

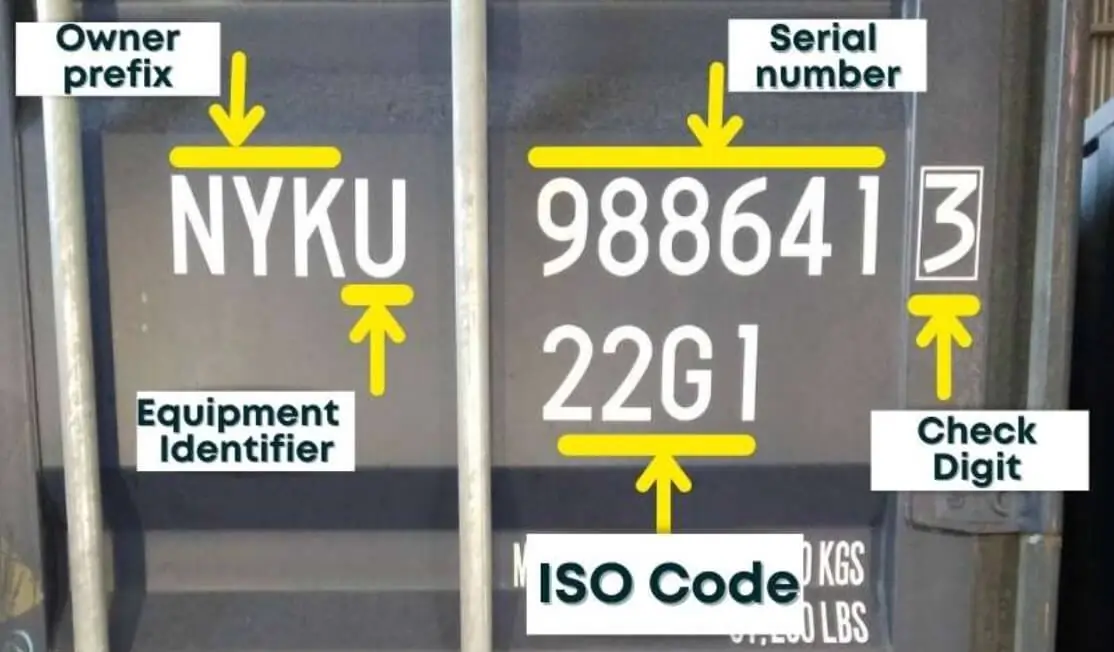

First up, tare weight. This is simply the shipping container weighing empty, without any cargo inside. It’s important to know your container’s empty weight for determining the total load you can safely carry, as well as for calculating transportation costs, since it affects the fuel efficiency and handling requirements during transport.

Next, gross weight. This is the total weight of a shipping container when it’s fully loaded. Knowing how much a shipping container weighs when fully loaded helps in avoiding overloading, which can lead to fines and logistical challenges.

Lastly, there’s payload capacity. This figure tells you how much cargo weight a container can safely handle. To calculate the payload capacity, just subtract the tare weight from the gross weight. This measure ensures that the container is not overloaded.

20ft Shipping Container Weight & Dimensions

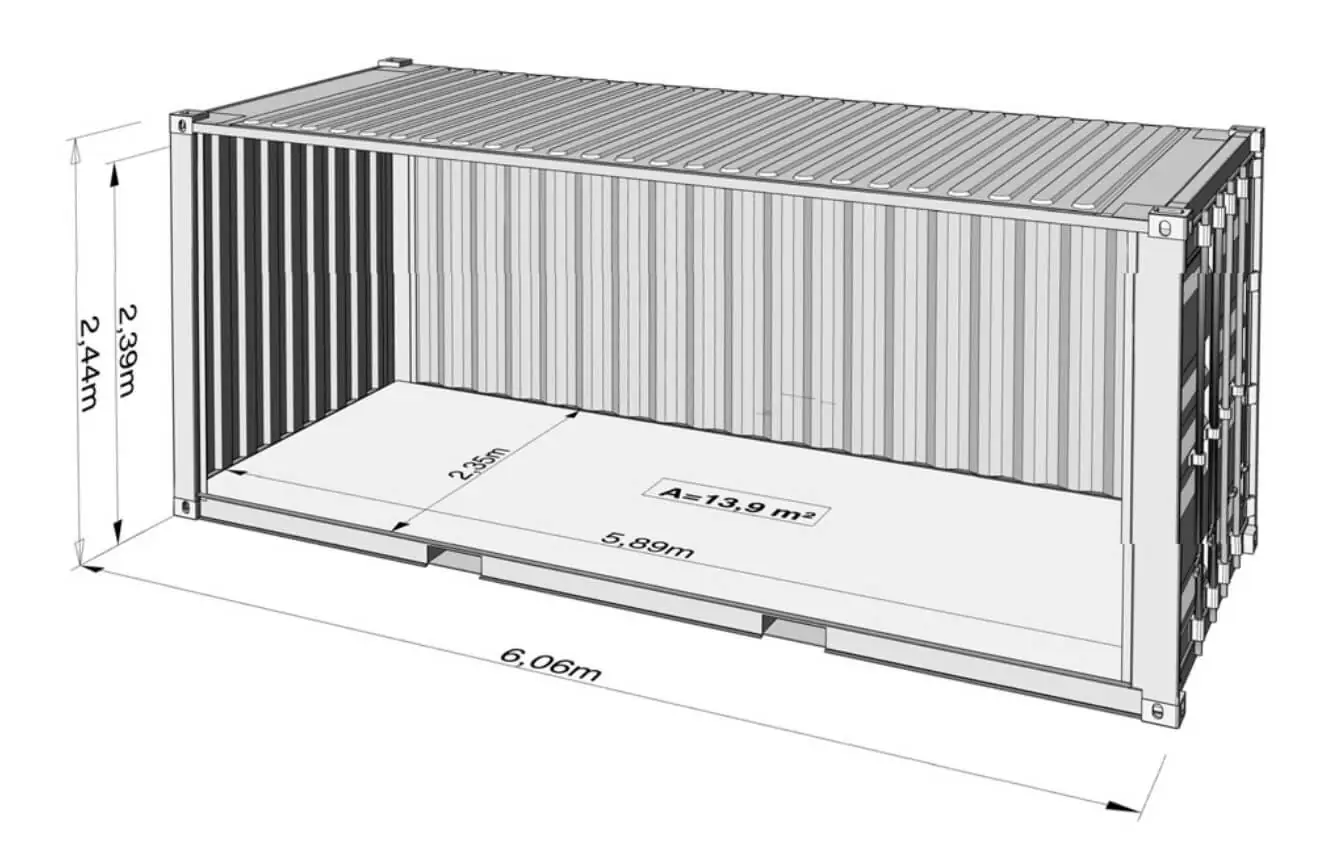

So, how much does a 20ft shipping container weigh? The empty shipping container weight, or tare weight, is typically around 2,080 kilograms (4,585 pounds). This is akin to the weight of a mid-sized SUV — here’s how you can feel a sense of its robust structure even before any cargo is loaded.

Now, when you pack it to its fullest, the gross weight of a 20ft shipping container reaches up to 30,480 kilograms (67,200 pounds) — like if you fill your SUV with several elephants. The payload capacity, which tells you how much cargo weight it safely handles, is approximately 28,500 kilograms (62,610 pounds). You remember this is calculated by subtracting the tare weight from the gross weight.

In terms of dimensions, a standard 20ft container measures about 6.058 meters (20 feet) in length, 2.438 meters (8 feet) in width, and 2.591 meters (8.6 feet) in height — ideal for transporting goods ranging from personal belongings to commercial products.

40ft Shipping Container Weight & Dimensions

How much does a 40ft shipping container weigh? The empty weight of a 40′ shipping container, or tare 40′ container weight, typically hovers around 3,500 kilograms (7,716 pounds). The 40 ft container weight is comparable to a large pickup truck.

Now, imagine filling this container to its brim. The gross 40′ container weight can reach up to 32,500 kilograms (71,650 pounds), an immense amount of space to transport a variety of goods. The payload capacity is approximately 29,000 kilograms (63,930 pounds).

The dimensions of a standard 40ft container are about 12.192 meters (40 feet) in length, 2.438 meters (8 feet) in width, and 2.591 meters (8.6 feet) in height. This container is spacious and elongated enough for shipping bulky items or large quantities of goods.

40ft HC Shipping Container Weight & Dimensions

The tare weight of a 40ft HC shipping container is approximately 3,760 kilograms (8,290 pounds) (about the weight of a small RV). The gross weight of a 40ft HC shipping container sometimes reaches up to 32,500 kilograms (71,650 pounds). The payload capacity stands at around 28,670 kilograms (63,210 pounds). T

Extra height sets the 40ft HC container apart. It maintains a length of 12.192 meters (40 feet) and a width of 2.438 meters (8 feet), and its height extends to about 2.896 meters (9.6 feet). This means more room for tall items and increased volume without changing the footprint.

How to Weigh a Shipping Container?

It’s impossible to imagine perfectly planned logistics without knowing the exact shipping container weight. There are several reliable container weighing methods:

- A weighbridge. This large, heavy-duty scale is typically installed at shipping facilities and is designed to weigh vehicles and containers. Here’s how it works. The truck carrying the container drives onto the weighbridge. The weight of the truck is recorded first, then the container is weighed either by itself or while still on the truck, subtracting the truck’s weight to determine the container’s weight.

- Portable scales. They are convenient for sites without a fixed weighbridge and can be easily transported and set up. To weigh a shipping container, the portable scales are placed under each corner of the container. The scales then provide individual weight readings that can be further summed to obtain the accurate container weight.

- Load cells. They are often used in automated systems or industrial settings. These devices are strategically placed under the container and measure weight based on the pressure exerted by the load. Load cells provide precise measurements and are ideal for operations needing constant monitoring of container weights.

If you know how to weigh a shipping container, you can optimize shipping processes, reduce costs, and adhere to safety regulations.

Why is it Important to Know the Container Weight?

Anyone in logistics or shipping should know the container weight, and here’s why:

- Safety. An overloaded container can tip over or damage vessels during transit. The exact container weight ensures your cargo is safely within limits, thus protecting both goods and people.

- Cost management. Shipping fees often depend on weight. Accurate container weight helps avoid surprise charges and optimize loads, and saves money by potentially consolidating shipments or adjusting loads.

- Regulatory compliance. Many regions enforce strict cargo weight regulations. Non-compliance leads to fines and delays. Being aware of container weight ensures your shipments meet legal requirements.

So, don’t forget to measure the weight of your containers to protect your cargo and avoid fees for non-compliance with international shipping regulations. And if you ever need expert advice, remember that Pelican Containers’ experienced specialists know everything about shipping containers, their dimensions, safety rules, and legal requirements.

Conclusion

Measuring container weight enhances safety, prevents accidents, and protects both cargo and personnel. You gain better control over costs, avoid unexpected fees, and optimize shipment loads. Staying compliant with regulatory standards safeguards your operations from fines and delays.

Vanessa is a dedicated writer and content enthusiast at Pelican Containers. With a background in practical writing and a keen eye for clarity, she transforms complex container topics into easy-to-understand and useful content. Her passion lies in exploring the evolving world of container usage — from smart storage hacks to global logistics trends.

When she's not writing, Vanessa loves discovering creative shipping container projects or traveling to find new inspiration.

Explore thoughtful, informative, and accessible content with Vanessa!

Vanessa is a dedicated writer and content enthusiast at Pelican Containers. With a background in practical writing and a keen eye for clarity, she transforms complex container topics into easy-to-understand and useful content. Her passion lies in exploring the evolving world of container usage — from smart storage hacks to global logistics trends.

When she's not writing, Vanessa loves discovering creative shipping container projects or traveling to find new inspiration.

Explore thoughtful, informative, and accessible content with Vanessa!

FAQ

How does the weight of a shipping container affect transportation costs?

The weight of a shipping container directly impacts transportation costs as shipping fees are typically calculated based on weight. Heavier containers incur higher costs due to increased fuel consumption and potential surcharges from carriers.

What factors can influence the overall weight of a loaded shipping container?

The type and density of the cargo, packaging materials, and the weight of the container itself usually affect the overall weight of a shipping container. Additional items such as pallets, dunnage, and securing materials count too.

Are there weight restrictions for shipping containers on certain routes or by specific carriers?

Yes, there are often weight restrictions imposed by carriers and regulatory bodies. They vary depending on the route, mode of transportation, and region. Exceeding a 20′ or 40′ container weight limit kg leads to fines or shipping delays, so always check ahead.

How can you accurately calculate the total weight of your cargo and container?

Weight the empty container (tare weight), then add the weight of the cargo, packaging, and any additional materials used for securing the load. Use a weighbridge or portable/load scales and verify weights with your supplier to ensure accuracy. Some companies also use specialized software to manage and calculate shipping weights.