Shipping Container Vents: Enhancing Airflow for Efficient Transport

What’s a ventilated container?

Ventilated cargo containers feature specialized air vents or openings. Typically, these ventholes are located along the container’s top and bottom side rails. Sometimes airflow pathways can be custom-designed to suit particular types of cargo ‒ wheat, coffee, and other temperature and humidity-dependent substances. Venting a shipping container is essential for these goods.

What are ventilated containers used for?

Not venting a shipping container can result in the most unpleasant consequences. Here are the most nasty of them:

Condensation

Condensation is simply the water vapor becoming liquid. It happens when temperature fluctuations rapidly increase the relative humidity in the air. Condensation is manifested as water drops.

Typically, condensation appears against the inside wall. This kind of moisture deteriorates packaging, and also causes an array of other negative effects listed below. These could simply be prevented by venting shipping containers.

Mold

It is one of the side effects of excessive condensation developing inside a shipping container. Moisture combined with high temperatures leads to the mold appearance that corrupts fabric, food, paper, packaging, and more.

This problem is of the outermost importance to prevent by implementing shipping container vents. Other interventions like treating surfaces with some sort of disinfectant have a very limited and temporary effect.

Fumes

Surprisingly enough, most types of cargo may produce poisonous fumes. Not necessarily toxic substances like oil or chemicals can generate fumes. Simply heated plastic alone can produce enough gasses for them to be dangerous.

Ventilated shipping containers cope with fumes easily, but airtight ones without a conditioning system just do not allow any gasses to form inside. The main issue with gasses is a bad smell caused by different toxins. Once a container is opened, they can be released and affect the workers.

Rust

Shipping containers aren’t cheap. They are expected to last for years without any deterioration. Yet, rust is another issue that occurs frequently. It is closely connected to excess moisture and raises when metal is exposed to water drops for a prolonged time.

Rust corrupts most metals that are commonly used for container box fabrication. It causes cracks and may even corrupt the packaging of items itself. In the worst-case scenario, rust leads to holes in the surface of containers if neither prevented nor treated properly.

Heat Build-Up

The steel is used to make the containers absorb heat. So, under direct sunlight, this unit can feel like inside an oven. Not even mentioning the usage of steel containers as homes, a box of heated metal is not a great storage area overall. All the sensitive types of cargo and even some comparatively durable items can be easily damaged if the temperature exceeds a certain level.

Additionally, flammable substances, such as petroleum or fuel oils, are often transported in containers. So you really need to know how to vent a shipping container to prevent those from exploding once the temperature inside breaches its flash point.

Construction of ventilated containers

Even while the majority of ordinary containers include tiny air vents, they’re usually insufficient to provide the kind of ventilation needed to keep weather-sensitive cargo fresh. This is where you need a vented container.

To ensure proper container ventilation, the airflow pathways are built with larger vents. Larger vents essentially let air move within the container, controlling the interior temperature.

Moisture builds up inside confined spaces without sufficient ventilation, harming the products within the container as well as the walls inside. Because any kind of weather can harm cargo of all types, container vents are also specifically made to keep rain and sea spray out of the container.

Types of container ventilation

Fortunately, there are several methods for reducing temperature and preventing moisture accumulation using natural airflow. Container ventilation systems can be installed by professionals or even by container owners themselves. The cooling effect of the system can be improved by insulating the entire container. Your options here include:

Shipping container air vents. Vents operate best when installed on opposite sides of a container. This permits the wind to blow fresh, dry air into the unit while allowing hot air to exit through the air vent on the opposite wall, providing natural airflow and temperature reduction.

Storage container vents. Storage container ventilation is imperative. The existing vents might suffice if you’re storing non-temperature sensitive equipment or products in a temperate climate. Keep in mind that these small vents only allow for a small amount of airflow.

Conex container ventilation. Installing vents on your containers allows air to flow in and out easily. The most popular term for this is cross ventilation. You install vents on the side of your container to allow air to go through. Then you should put vents on the other side of your container.

Regardless of the chosen type, the end result is always the normal ventilation inside your shipping container. Natural air circulation will prevent or notably reduce all the negative effects.

Ventilated cargo container vs standard dry container

So, if both ventilated and standard dry containers have vents, what is the primary difference between them?

Venting a shipping container, a dry one, requires a few small vents. However, for a ventilated container the very construction of vents suggests constant airflow. These vents are bigger both in number and size, and you can easily spot them on the sides of the container.

Why use a ventilated container?

Ventilation for shipping containers helps to maintain a suitable interior temperature by freeing it from fumes from fuel, paints, and other substances. It also removes moisture and condensation from the ceiling. Besides, installing vents in a storage container is the ideal solution to excessive condensation that forms inside the container during temperature fluctuations.

Basically, shipping container ventilation performs three essential functions: it enables the circulation of air, limits the effects of temperature fluctuation, and reduces the excessive humidity in air and condensation.

Dimensions of ventilated shipping containers

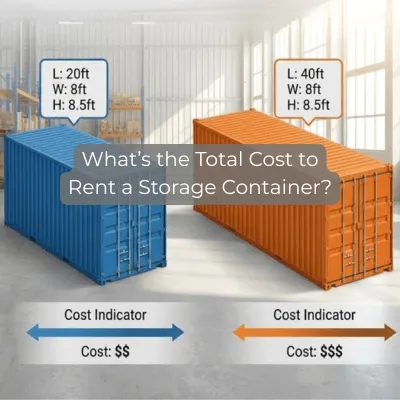

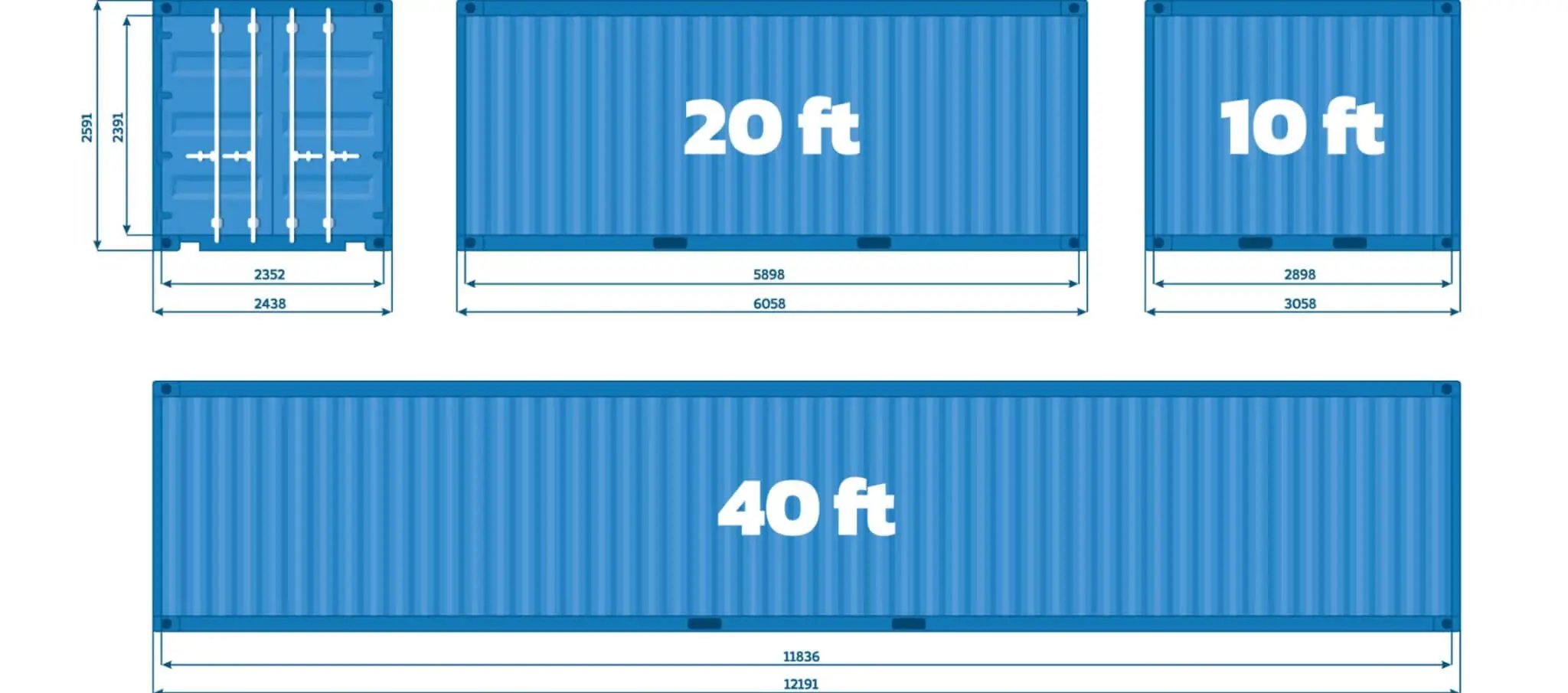

Most ventilated containers have the same dimensions that standard dry do:

- 20ft ‒ small and efficient, perfect for easy loading and transporting cargo between different carriers;

- 40 ft ‒ double capacity, more cost-efficient for big cargo volumes.

And, of course, there are 45 HC and other less common types of containers ‒ they can have ventilation systems installed as well.

Other container types: Standard and special containers for shipping and storage

It’s actually simple ‒ a cargo that has to remain dry needs your usual standard dry container, be it 20ft, 40ft, or 40ft HC for additional height. Lastly, if you need even more storage space, you can opt for 45ft HC dry containers.

If you need transportation of humidity and temperature-dependant items (medicine, dairy or meat products), look for a refrigerated container.

For stuff that requires extra dimensions and can’t be fitted into standard containers, opt for a flat rack ‒ these have no side walls and no roof.

How do you add ventilation to a storage container?

Inherently, airtight shipping containers are used for various purposes. For one, they are used in transporting products across the ocean regardless of weather conditions. Because goods must not be exposed to corrosive saltwater when inside. Yet, the use of the hermetic sealing can cause some deteriorative effects.

Besides, using containers as living spaces is quite complicated, because they need to be ventilated. Containers are pretty much the same as buildings in this regard. Therefore, if you consider purchasing a container box, you should consider the installation of air systems in shipping containers.

5 Reasons Why You Need One Trip Shipping Container | New Shipping Container

In many cases, buying new or doing a one-trip is the best option. One-trip shipping containers are the way to go if your needs cater to some aspects mentioned above.

Vanessa is a dedicated writer and content enthusiast at Pelican Containers. With a background in practical writing and a keen eye for clarity, she transforms complex container topics into easy-to-understand and useful content. Her passion lies in exploring the evolving world of container usage — from smart storage hacks to global logistics trends.

When she's not writing, Vanessa loves discovering creative shipping container projects or traveling to find new inspiration.

Explore thoughtful, informative, and accessible content with Vanessa!

Vanessa is a dedicated writer and content enthusiast at Pelican Containers. With a background in practical writing and a keen eye for clarity, she transforms complex container topics into easy-to-understand and useful content. Her passion lies in exploring the evolving world of container usage — from smart storage hacks to global logistics trends.

When she's not writing, Vanessa loves discovering creative shipping container projects or traveling to find new inspiration.

Explore thoughtful, informative, and accessible content with Vanessa!

FAQ

What are the primary benefits of using ventilated shipping containers for transporting goods?

They provide improved air circulation, which helps prevent moisture buildup and reduces the risk of mold and mildew. This is especially important for perishable goods and items sensitive to humidity. The ventilation also helps with maintaining a more stable internal temperature, protecting the cargo from extreme temperature jumps in transit.

How does a ventilated shipping container differ from a standard shipping container?

The key difference between a ventilated shipping container and a standard shipping container lies in the ventilation features. Ventilated containers have specially designed air vents or openings that promote airflow, when standard containers go without these ventilation systems. This distinction makes ventilated containers more suitable for transporting goods that need a controlled environment with good air circulation.

Which types of cargo are best suited for ventilated shipping containers?

Ventilated shipping containers are perfect for transporting goods that are sensitive to humidity and temperature. This includes agricultural products like coffee, cocoa, grains, and fruits, as well as certain textiles and wood products.

What are the common challenges and solutions when using ventilated shipping containers?

One common challenge with ventilated shipping containers is managing the potential for external particles entering through the vents. This can be fixed by using filters or screens to cover the vents and prevent dust, insects, or other debris from entering. Another challenge is ensuring the container vents are not obstructed during loading and unloading, which can be arranged by proper packing and careful handling of the cargo.

How can I maintain and ensure the longevity of a ventilated shipping container?

Check shipping container vents for blockages, damage, or signs of wear, and clean or replace filters as needed. Regularly inspect the container’s structural integrity, including the doors, seals, and walls. Properly store the container when not in use to protect it from environmental elements, and follow manufacturer guidelines for any specific maintenance requirements.