How the Invention of Shipping Containers Changed the Logistics Industry

The logistics industry has come a long way by virtue of technological advancement in every aspect of its lifecycle. The introduction of several sophisticated equipment, real-time tracking system and specially designed cargo-bearing ships and trucks have considerably reduced cost and time while increasing accuracy and efficiency. However, if we have to pick one item without which the industry will struggle to function at its optimum level, it won’t be anything high-end from the list above.

Any guesses?

Yes! We are talking about shipping containers. These humble steel and aluminium boxes have revolutionized the way the cargo used to be loaded, shipped and unloaded in the past.

The container chronicle

The history of shipping containers dates back to 1956 when an old tanker ship carried 58 aluminium boxes to the port of Houston from where they were hauled by 58 trucks to their destination. This was the first instance of cargo shipping via metal boxes; a way forward from the usual method of loading, sending and unloading individual items separately by the wharfies. Soon businesses started realizing how shipping containers could bring standardization in the logistics processes thereby benefiting every stakeholder.

How the containers brought standardization?

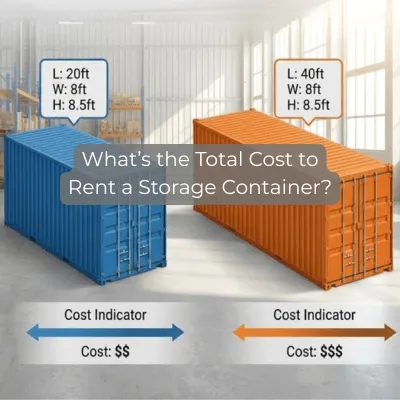

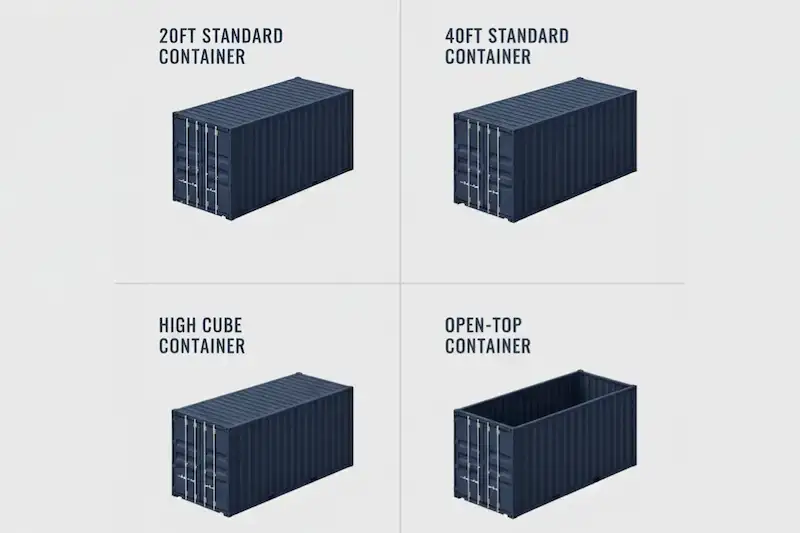

Shipping containers can move almost everything apart from bulk commodities, thus minimizing handling cost to a great extent. The cargo, when loaded inside a container, can be moved from door to door, truck to ship or train to truck without any further handling. Most of the containers are of the same shape and dimensions, (eight feet wide, eight feet high and 20 or 40 feet long container), and have similar features (aluminium or steel body, weather-proof wood flooring, and two robust doors). A fully loaded container can weigh anywhere between 27 and 36 tonnes. A typical container ship can carry about 3000 such boxes in stacks of six or seven. All these attributes make these boxes a powerful tool for standardization which, in turn, facilitates automation. The whole process of automation is further improved by computerization by virtue of which the containers, each carrying a unique number, can be tracked throughout its journey.

The effect of technology

The effect of standardization continued both in the vehicles and ports which are purpose-built to accommodate the shipping containers. Technology helps in reducing processing time. As a result, ports are now moving up to 10,000 containers a day. Currently, container ships can be unloaded and loaded at the same time and within 24 hours using cranes. Each crane can move 30 or 40 containers an hour. Since reduced time accounts for reduced cost, today, millions of shipping containers carry goods effortlessly around the world at a much lesser cost; thus boosting the economy and business prospects.

Network economies

Another boon of standardization is ‘network economies’ which essentially means that the appeal of the containers increases with the influx of its users. Also, an increase in the number of new users ensures greater benefit to its existing users.

Why did containerization work?

Containerization worked in the logistics industry as it was able to reduce the transport cost to a great extent. Earlier, the cost of moving cargo individually from the truck to ship and ship to truck accounted for more than half of the total shipping cost. With the introduction of huge container ships, which are able to carry way more cargo with fewer crews, the shipping cost is reduced further. The obvious benefit of reduced transport costs is increased trade – both domestic and international.

Containerization allowed manufacturers to spend more on other aspects of the business when the transport cost fell. Many of them delved into export turning a lot of firms into transnational corporations. Containerization made ways for ‘just-in-time manufacturing’, where a supplier makes the goods only after a customer places a demand for it and then ships them, in containers, to arrive at a specified time. This has led to massive reductions in manufacturers’ inventories and correspondingly huge cost savings. Retailers have applied the same method to reduce their own inventory costs.

The effect of containerization on economic geography is also significant. Earlier, the manufacturers used to locate nearer to their customers to avoid high transport cost. However, now they have the liberty to move where the land or labor is cheaper.

The adverse effect of containerization

Containerisation made a lot of (once popular) ports lose their glory as they were nor spacious enough to accommodate huge container ships. It also had a huge impact on the stevedoring industry with thousands of wharf laborers losing their jobs. There have been protests from all over the world. However, the new jobs that emerged from increased trade far outweighed the negatives. Hence, the pros of containerization were greater than the cons – at least from a business perspective.

The invention of the shipping containers is a fascinating example of how technological change plays a deciding factor in shaping the future of an industry.

What’s The Best Shipping Container Delivery Option To Ship Your Container?

Getting your container delivered is as important as buying the perfect shipping container. At Pelican Containers, we are delighted to provide helpful assistance tailored to your specific needs. Basically there are three standard container delivery methods. Tilt-Bed Delivery: The most common delivery method is a tilt-bed, which can be used with a straight vehicle or a tractor-trailer combination. Flat-Bed Delivery: Long flatbed trucks can carry one 40′ container or up to two 20′ containers. Your container will be placed on the truck using a forklift or crane. Chassis Delivery: A chassis is a metal frame with wheels that is pulled by a trailer and is designed to carry containers safely. The optimal shipping option for you will depend on how you want to use your container.

Vanessa is a dedicated writer and content enthusiast at Pelican Containers. With a background in practical writing and a keen eye for clarity, she transforms complex container topics into easy-to-understand and useful content. Her passion lies in exploring the evolving world of container usage — from smart storage hacks to global logistics trends.

When she's not writing, Vanessa loves discovering creative shipping container projects or traveling to find new inspiration.

Explore thoughtful, informative, and accessible content with Vanessa!

Vanessa is a dedicated writer and content enthusiast at Pelican Containers. With a background in practical writing and a keen eye for clarity, she transforms complex container topics into easy-to-understand and useful content. Her passion lies in exploring the evolving world of container usage — from smart storage hacks to global logistics trends.

When she's not writing, Vanessa loves discovering creative shipping container projects or traveling to find new inspiration.

Explore thoughtful, informative, and accessible content with Vanessa!