What is CFS shipping? Get an overview & its benefits for your business

Shipping isn’t just about boxes on boats. Before anything gets to a port, and long before it hits a store shelf, there’s a mess of paperwork, storage, loading, and inspection happening somewhere. That somewhere is often a Container Freight Station — CFS for short. If you’ve ever tried to move cargo without paying for a full container, you’ve already brushed up against it, whether you knew it or not.

The CFS is where things get packed together, unpacked again, sorted, labeled, checked, and sometimes just left sitting until customs clears them. It’s not fancy, but it’s essential. And if you’re running a business that ships goods in or out, especially in smaller batches, ignoring what happens at a CFS is going to cost you both time and money.

This isn’t just another acronym in the shipping world. Understanding CFS, how it’s different from CY, and what you’re actually paying for when your goods go through one can make a big difference in how you plan, budget, and move your cargo. Whether you’re dealing with flat rack loads, pallets of electronics, or oversized stock in a 40ft high cube double door container, this is where your shipment’s real journey begins.

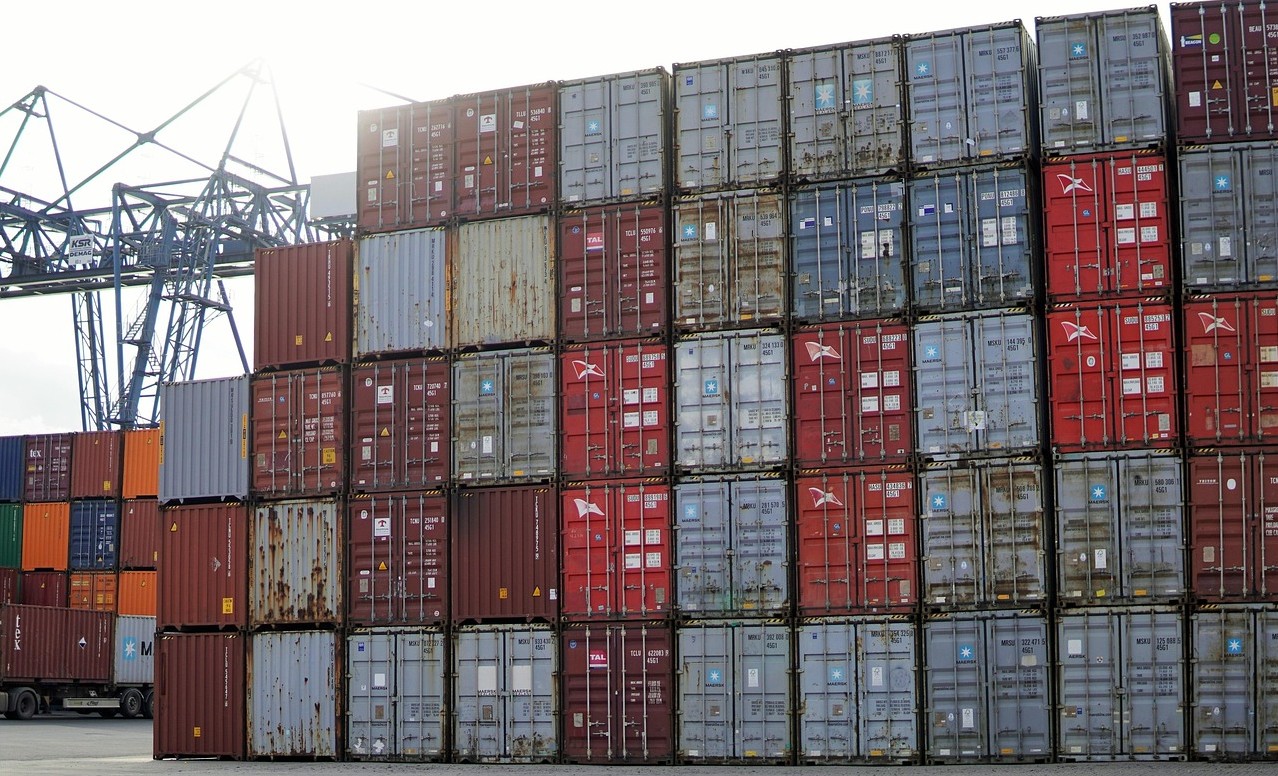

What is a Container Freight Station (CFS)?

Before being loaded into shipping containers, a cargo is packed and consolidated. It is done at a Container Freight Station (CFS). You can think of it as a sorting hub to organize goods before letting them go to their destination. CFS is especially beneficial for less-than-container-load (LCL) shipments, where a single container is used to store multiple shipments.

These stations handle receiving, storing, and dispatching freight. When dealing with smaller loads or shipments of multiple origins and destinations, CFS facilities give companies a healthy level of flexibility. A good example: if you’re transporting your cargo in high cube containers, the goods can go through a CFS for sorting and packing before being shipped internationally.

Why is understanding CY and CFS needed in shipping

Understanding these notions can serve you well in the long run, so let us break them down.

A Container Yard (CY) is a storage area where full containers are kept before being loaded onto trucks or ships. It’s mostly used for full-container-load (FCL) shipments, where a single customer fills an entire container.

On the other hand, a Container Freight Station helps LCL shipments optimize space and lower costs for companies that don’t have enough goods to fill a full container.

What are the functions of a Container Freight Station

A CFS makes a solid difference in the shipping process, and the reasons for that include:

- Cargo consolidation: CFS facilities gather goods from multiple customers into one container, which helps optimize space and reduce shipping costs. This benefit mostly applies to LCL shipping.

- Cargo unloading and packing: before being shipped to the final destination, goods are either loaded or unloaded at the CFS.

- Customs clearance: many CFS facilities offer customs brokerage services, assisting in the process of customs clearance for import and export goods.

- Storage: goods can be stored at CFS facilities for short-term periods, providing flexibility in the timing of shipments.

- Freight dispatching: CFS also handles the dispatching of goods to their next destination, whether that’s another port, a truck, or a train.

With such an arsenal of benefits, shipping logistics acquire the swiftness and security so needed in freight operations.

How does CFS shipping help your business

Companies, especially those dealing with international cargo, benefit from CFS shipping in numerous ways. Here’s how:

- Saving money. Sharing container space with other shippers can significantly lower shipping costs. Smaller companies that don’t need an entire container for their goods may find this especially handy.

- Flexibility. CFS gives plenty of room in terms of shipment sizes and storage. If your goods are too small for a full container, you don’t have to pay for space that you don’t use.

- Simplicity. A CFS allows consolidating, pack, and dispatch goods from one central location. This can save time and reduce the probability of mistakes in how your cargo is handled.

- Reduced risk. With security measures in place at CFS facilities, goods are kept secure while they’re waiting for shipment. Many facilities also provide cargo insurance options, adding another layer of protection for your business.

For instance, when you choose to ship with Pelican Containers, you can opt for various container options like flat rack containers or open-side shipping containers, depending on the nature of your cargo.

What is included in CFS shipping charges?

When dealing with CFS shipping, charges typically cover a range of services. These include:

- cargo handling fees: costs associated with loading, unloading, and consolidating goods at the CFS;

- storage fees: if your cargo needs to be stored at the CFS for an extended period, you’ll incur storage charges;

- customs fees: if the CFS is handling customs clearance, there may be additional charges for this service;

- freight forwarding fees: associated with moving your goods from the CFS to their next destination.

To ensure better control of your budget, you may ask for a breakdown of charges when planning your shipment.

What is CFS in shipping vs. CY in shipping?

Both CFS and CY are important entities in the shipping industry, but they serve different purposes. Let’s break them down:

- CFS (Container Freight Station): used primarily for LCL shipments. It’s where goods are consolidated into a container for shipping.

- CY (Container Yard): used for FCL shipments. It’s where full containers are stored and prepared for departure.

The main difference is that CFS is more geared toward smaller, shared shipments, while CY is for large, full-container loads. Armed with this knowledge can help you make more weighted decisions regarding which type of facility is right for your business.

By the way, if you need secure and efficient shipping container options, take a look at 40ft high cube double-door tunnel containers.

Final thoughts on working with CFS for shipping needs

Container Freight Stations make it easier to deal with international cargo, especially when you’re not shipping at scale. They help cut down storage costs at ports, offer organized cargo handling, and simplify the customs process. Businesses that want to move products quickly without committing to FCL shipments benefit the most from CFS services.

Shipping costs are more predictable when you’re not paying full container rates. If you’re managing regular imports or exports, using a station where cargo can be collected, sorted, and dispatched under one roof gives you flexibility. Whether you’re loading standard pallets or oversized items into 40ft high cube containers, having a CFS involved in the chain improves the overall flow of goods.

Understanding how CFS and CY differ also prepares you to ask the right questions when booking freight. That knowledge puts you in a stronger position when dealing with logistics providers or negotiating storage and dispatch timelines. The more informed you are, the better deals you can cut — and that matters in any business trying to keep shipping costs low while reaching multiple destinations.

Vanessa is a dedicated writer and content enthusiast at Pelican Containers. With a background in practical writing and a keen eye for clarity, she transforms complex container topics into easy-to-understand and useful content. Her passion lies in exploring the evolving world of container usage — from smart storage hacks to global logistics trends.

When she's not writing, Vanessa loves discovering creative shipping container projects or traveling to find new inspiration.

Explore thoughtful, informative, and accessible content with Vanessa!

Vanessa is a dedicated writer and content enthusiast at Pelican Containers. With a background in practical writing and a keen eye for clarity, she transforms complex container topics into easy-to-understand and useful content. Her passion lies in exploring the evolving world of container usage — from smart storage hacks to global logistics trends.

When she's not writing, Vanessa loves discovering creative shipping container projects or traveling to find new inspiration.

Explore thoughtful, informative, and accessible content with Vanessa!

FAQ

What is the difference between FCL and CFS?

FCL (Full Container Load) means one shipper uses the entire container. It’s sealed at origin and opened only at the final destination. No one else’s cargo gets mixed in. CFS (Container Freight Station) is for LCL (Less than Container Load) cargo. Multiple shipments from different shippers are packed into the same container at a CFS, then unpacked at another CFS after arrival.

What is a CFS charge for shipping?

CFS charges cover the handling and processing of cargo at the station. This can include loading, unloading, sorting, paperwork, storage, and customs support. You’re paying for the services involved in grouping your shipment with others and getting it in or out of a container — not just the container space itself.

What are the benefits of CFS?

CFS shipping cuts costs if you’re not shipping enough to fill a container. It also gives more flexibility with shipment sizes and timing. You can collect cargo from different suppliers and send it out together. You also don’t have to deal with the port directly — CFS staff handle customs and sorting.

What are the disadvantages of CFS?

It takes longer. Your cargo waits for other shipments to arrive before the container is full. Delays are possible at both the origin and destination. There’s more handling, which increases the chance of damage or misplacement. And since other people’s goods are packed with yours, you don’t control the schedule.

How does the CFS work?

Cargo gets dropped off at the CFS, logged, labeled, and sorted. It’s packed into a container with shipments from other exporters. Once the container is full, it moves to the port. At the destination, the container goes to another CFS. It’s unpacked, sorted by recipient, cleared by customs, and released for delivery.