7 Steps For Stopping Shipping Container Condensation

Moisture buildup due to condensation in shipping containers can occur in storage or transit and cause harm to cargo if not handled. Many circumstances can cause moisture humidity in shipping containers. So effective shipping container moisture control is essential to prevent condensation and humidity issues that can damage the contents of the container during transportation or storage.

This article will explain why moisture buildups are a concern and how to keep moisture out of shipping containers. We present seven steps you can take to keep condensation out of shipping containers.

What are the Causes of Condensation in Shipping Containers?

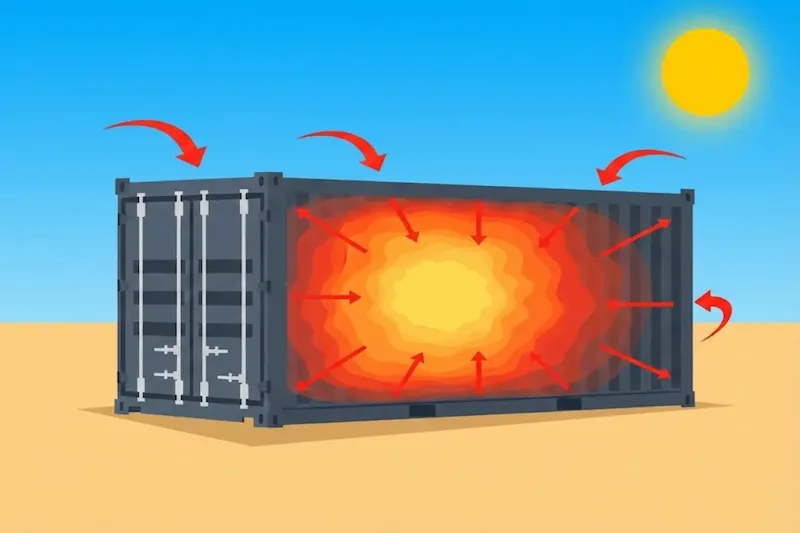

Condensation is water vapor returning to its liquid form, having reached the dew point temperature. Inside a shipping container, condensation appears as drops that can “rain down” on the cargo. Stopping condensation in shipping containers will keep your cargo safe.

Condensation most often occurs on the container’s ceiling and the top of the interior sidewalls. These are the most common causes of condensation in shipping containers.

- Exterior water sealing is insufficient – If the roof and wall seams of the container are not appropriately sealed: rain, melting snow, seawater, and surface runoff all have the potential to carry liquid water inside the container.

- Damp materials inside the container – If the inside of the container was exposed to water, the wooden floor might still be damp, or the water may still reside beneath it. The water inside evaporates and condensates on the container surface when the outside temperature goes down.

- Difference in atmospheric pressure – Outside air can be drawn into the structure through open vents or air leaks when the inside pressure of the container is lower than the outside pressure. Moisture can also enter the container when the outside air is warm and humid.

- Rusted container surface – Shipping containers can be exposed to a large amount of seawater that provokes rust. Even the slightest scratch can grow into a rusted surface if the container is poorly maintained.

- Punctured container surface – Transporting heavy cargo can lead to accidents damaging the container during loading and unloading. Anything that can let in moisture and water can lead to condensation when the trapped water evaporates and then settles on the inside surfaces of the container.

Danger of Moisture in the Shipping Container

When water vapor becomes liquid, water drops can pool on the container ceiling and walls. Fluids in a supposedly dry container can cause irreversible damage to your cargo. This is why it’s imperative to know how to stop moisture in a shipping container and how to keep a shipping container dry.

- Damage to metallic cargo: Condensation problems in shipping containers can cause rust on metallic cargo, making them visually unappealing and weakening them. The sensitive part of vehicles, tools, and machines can also rust, especially when shipping takes a long time.

- Damage to wooden cargo: Water can cause wood to swell, weaken, and rot.

- Damage to electronic components: Condensation can trigger chemical reactions in materials such as fasteners, wire, PCBs, solders, and electrical coils, resulting in corrosion. Moisture in shipping containers can also increase the conductivity of insulators in electronic devices, leading to short circuits.

- Damage to labels or packaging of retail products: Moisture can warp boxes of food products and stain the water labels of canned goods. Although it may not affect the quality of the product, the visual damage to the labels and packaging can be enough to dissuade purchase.

- Mold and mildew on food sacks: rice and grain are usually transported in sacks that must be kept dry at all times. Rice and grain cargo must be secured from container moisture in wet weather or when shipping overseas, as it can cause mold and spoilage.

- Health risks and slipping hazards: large amounts of moisture on the container floor can be dangerous. Shipping container condensation can generate unpleasant odors, posing additional health risks. This is mainly due to mold growth, which can aggravate cargo handlers’ allergies and asthma.

Shipping container condensation problems can be a significant challenge, especially during temperature fluctuations. Proper insulation and moisture control solutions are often required to mitigate these issues and protect the cargo inside.

How to Avoid Problems with Condensation in Shipping Containers?

Shipping container condensation can damage moisture-sensitive cargo and spoil food products.

How to stop condensation in a shipping container? Here are seven steps to ensure that your shipping container will not have condensation issues.

-

Install Ventilation

Ventilation is one of the most cost-effective solutions to reduce condensation and keep the cargo dry. Condensation can be reduced or avoided if air circulates through a shipping container. It balances the temperature of the air on the inside and outside.

-

Check for Rust and Damages

Shipping containers are mostly cor-ten steel, which is highly corrosion-resistant. However, it is not entirely corrosion-proof. Keep an eye out for any points of contact while transporting and stacking. The underside of doors can rust away if water pools beneath them for an extended period.

-

Clean and Dry Container Interiors

Proper maintenance is key to preventing condensation in shipping containers. The shipping containers must be cleaned correctly. This includes cleaning and sanitizing the container in between shipments, as well as eliminating any foreign objects. The container may be contaminated with harmful things such as mold, bacteria, fungi, dirt, and dust if it’s not regularly cleaned.

-

Choose the Right Pallet

Plastic pallets are around three times more expensive than wooden pallets. They are lightweight and waterproof but not designed to handle extremely heavy loads. But unlike wooden pallets, they are not porous and will not collect moisture. Moisture absorbed by wooden pallets has the potential to evaporate and create condensation. Plastic pallets are the best option if your cargo is vulnerable to moisture.

-

Use Desiccants and Shipping Container Dehumidifiers

Desiccants and dehumidification equipment absorb extra moisture from the air, resulting in less condensation within the shipping container. Bagged desiccants can be attached to the container wall or applied to container walls using spray applicators. A good rule of thumb is using about 40 grams of desiccant per cubic foot of container space. A shipping container dehumidifier will keep moisture trapped in humidity containers, but it will require a power source.

-

Apply Insulation

While tough and long-lasting, the steel walls of a shipping container may get quite hot during the day and very frigid at night. The stark changes in temperature can trigger condensation. That means you’ll need insulation if you store temperature-sensitive items like electronics or perishable food.

Lining a shipping container with insulation will keep the inside temperature from fluctuating and keep it above the dew point, preventing condensation. -

External Insulation

Dealing with shipping container home condensation is essential to ensure a healthy and dry interior. Homeowners often employ techniques like insulation, dehumidifiers, and well-placed vents to prevent condensation and create a more comfortable atmosphere within the container home. If you plan to use shipping containers for residential purposes, installing external insulation can help control the internal temperature to eliminate condensation. Spray foam insulation is one of the simplest and quickest ways to insulate a container home. This insulating compound can be sprayed directly onto a shipping container’s interior and exterior walls.

When looking for a shipping container condensation solution, it is essential to consider all technical factors, including proper insulation, ventilation, and humidity control measures. These elements are often used to prevent condensation and ensure the container’s reliable performance.

Final Thoughts

Choosing a good shipping container is crucial in transporting cargo safely. Hopefully, the article has shown you the dangers of having condensation in a closed container. Our steps should help you avoid condensation and keep your cargo dry, safe, and secure.

Pelican Containers is a trusted supplier of high-quality containers. We ship to all US states. If you need help in determining the best type of shipping container for your cargo, get in touch with our shipping experts. They can advise you on which container to buy and even help you apply all our anti-condensation recommendations.

Cure Inside A Shipping Container | Shipping Container Medical Clinics - Pelican Containers

Have you heard of shipping container-turned mobile clinics? Yes, they are a reality today; especially in remote areas where healthcare facilities are insufficient. These clinics can be made self-reliant by installing solar panels, onboard water treatment systems, and in-built batteries for back-up. They are also easily transportable on a truck, rail, and ship and come handy in war-zones, disaster-hit areas, and other far-flung places. Need one? Contact us today!

Vanessa is a dedicated writer and content enthusiast at Pelican Containers. With a background in practical writing and a keen eye for clarity, she transforms complex container topics into easy-to-understand and useful content. Her passion lies in exploring the evolving world of container usage — from smart storage hacks to global logistics trends.

When she's not writing, Vanessa loves discovering creative shipping container projects or traveling to find new inspiration.

Explore thoughtful, informative, and accessible content with Vanessa!

Vanessa is a dedicated writer and content enthusiast at Pelican Containers. With a background in practical writing and a keen eye for clarity, she transforms complex container topics into easy-to-understand and useful content. Her passion lies in exploring the evolving world of container usage — from smart storage hacks to global logistics trends.

When she's not writing, Vanessa loves discovering creative shipping container projects or traveling to find new inspiration.

Explore thoughtful, informative, and accessible content with Vanessa!

FAQ

What does condensation look like inside the container?

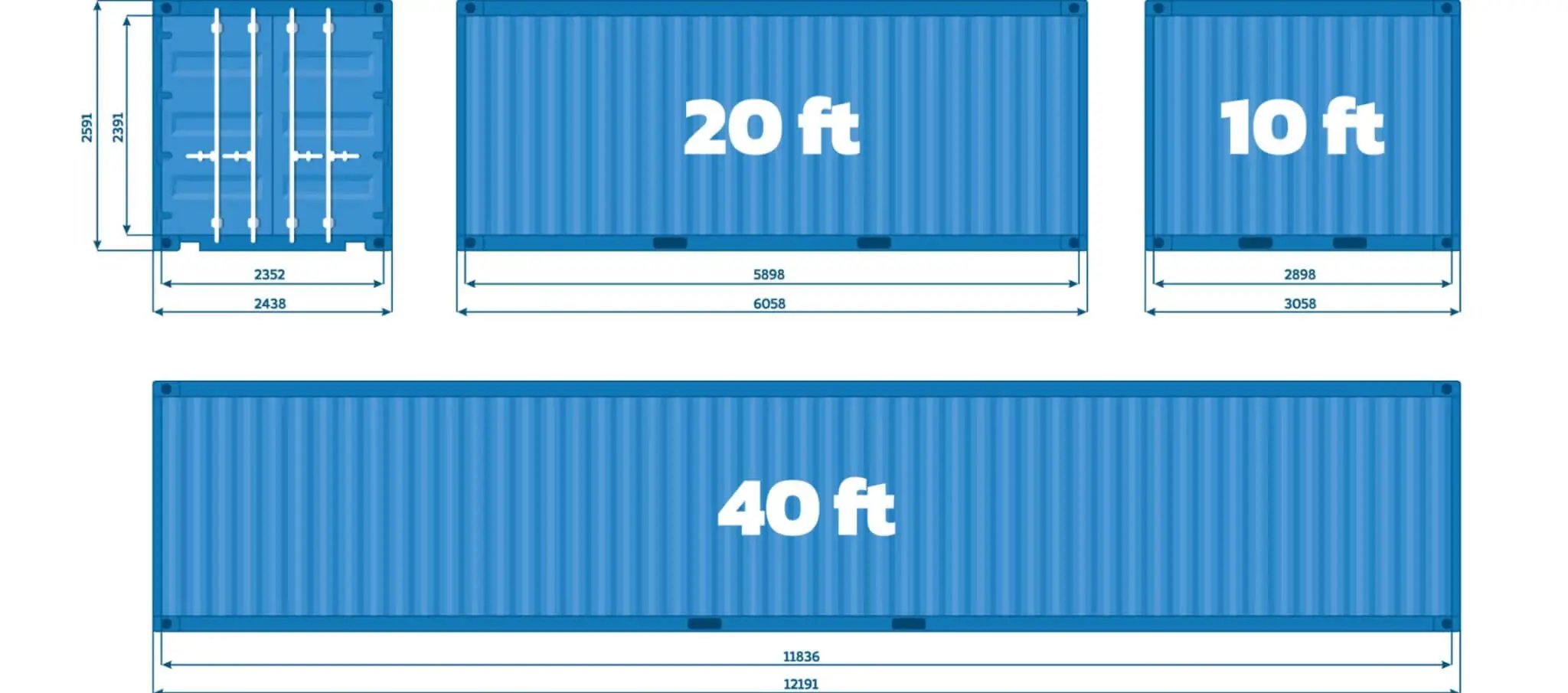

Condensation occurs in a closed container like a 20-foot high cube when the temperature dips below the dew point. It is the temperature at which water vapor in the air condenses to produce liquid water. When this occurs, the inside walls and ceiling of the container “sweat,” and the drops can drip. This “condensation rain” can potentially cause water damage to sensitive equipment and spoil grains or food.

What temperature does my shipping container need to be to not exceed the dew point?

The temperature at which water vapor condenses into water in any static or flowing air column is referred to as the dew point. In other words, the air is saturated at this temperature and can no longer hold moisture. Excess moisture is released as condensation when the air temperature falls below the dew point. This can occur at temperatures ranging from cold (32 Fahrenheit or zero Celsius) to hot (212 Fahrenheit or 100 Celsius). The wide temperature range is due to the effect of humidity; with more moisture in the air, the dew point rises.

What types of shipping containers are the most protected against condensation?

Well ventilated and closed containers are well equipped to repel moisture and condensation. However, adding inside insulation and desiccants can vastly improve a container’s resistance to condensation. If you have large but sensitive cargo, you can get a used container like a 40-foot standard container and line the insides with insulation and foam. This will control the inside temperature under dew point and keep any water vapor from condensing.