Shipping Container Flooring: Everything You Need to Know

These days, shipping containers are used for numerous purposes besides transporting goods overseas. Such containers are used by individuals and commercials, so it’s important to know what type of shipping container floors work best in each case. Here you can learn more about widely used flooring variants and their modern alternatives.

What Are the Widely Used Shipping Container Flooring Options?

There are a lot of shipping container floor options to choose from. The best options depend on the purposes for which containers are used. Sometimes it can be pretty challenging to make the right decision, so here you can read about popular types and their peculiarities.

Plywood #1

Plywood is undoubtedly the most widely used material for the flooring of shipping containers. It is a type of hardwood that is often made from the tropical Apitong and Keruing trees. Plywood is a top choice for many containers because it is durable, lightweight, and resistant to humidity.

The only significant disadvantage of plywood flooring is the fact that it is treated with antifungal solutions and pesticides. Those who plan to use containers as living or working spaces should look for other materials or completely replace the flooring upon arrival, as treatment flooring chemicals are dangerous for your health when using containers for residential purposes.

Bamboo #2

Another popular flooring material option is bamboo. As opposed to plywood, bamboo is usually treated with less potent chemicals. For this reason, it is often possible to get away with covering bamboo flooring in a coating and then putting new material over the underlay.

Steel #3

Another type of shipping container floor you may deal with is the steel one. This flooring is easiest to maintain and is often used in refrigerated containers. Steel is wear-resistant, recyclable, and also doesn’t require the use of any chemicals. A significant benefit of this material is that you don’t need to worry too much about how to maintain a shipping container.

Aluminum #4

In addition to the steel options, you can also find aluminum floors in containers. The material is also sturdy and ideal for various industrial purposes. Aluminum is water-resistant and makes it possible to create airtight containers. Another advantage is that it is easy to clean and it is odorless. In comparison to plywood, it is a more eco-friendly material.

What Modern Alternatives Are for Shipping Container Flooring?

Nowadays, numerous manufacturers of containers use modern alternatives to plywood flooring. The options differ depending on the intended purpose, but all of them don’t require chemical treatment, which is a serious advantage compared to plywood. Here are some modern types of shipping container flooring that you should know about.

Vinyl

Vinyl is one of the excellent alternatives to plywood. This material is known for its durability and is often used for transporting acids and oils. Vinyl flooring is easy to install and clean, so it is often used in containers that are turned into garages, portable bathrooms, and offices.

Another option to consider is coin vinyl, which has all the benefits of standard vinyl but is also slip-resistant. This type has coin-sized circles that are raised on the floor surface and thus achieve this effect.

Imitation Wood

When there is a need for the floor to be not only practical but also look good, imitation wood is the way to go. Such flooring is commonly made of PVC or vinyl in combination with composite wood. They are often made in the form of planks, similar to hardwood flooring, and their installation is straightforward and quick. This material works well when a container is used for residential or office purposes and not for transporting goods.

Carpet Tiles

If you are looking for a cost-effective and durable option, you should consider carpet tiles. This material is easy to find, long-lasting, and provides a cozier feel to the space. Carpet tiles are commonly used in home and office containers. They are not only resistant to tear and wear, but also have many options when it comes to color and design.

Epoxy Coating

Another option you may consider is epoxy coating. This type of coating is applied over the existing material to seal the shipping container floor structure. This solution can be used on different floors, such as bamboo and plywood.

Tips to Check Your Shipping Container Flooring

Now that you are familiar with the options of shipping container flooring, it’s also important to know how to properly check whether the material has been damaged or contains any chemicals. Before you begin any floor modifications, it’s a good idea to check what solutions and chemicals have been used to treat the original wood.

Take a Look at the Data Plate

Each container comes with the Convention for Safe Containers plate. In most cases, this label is located on the container’s front door. You should find the timber component treatment section on the plate for more information on what pesticides have been used on the flooring.

Make Sure to Check the Treatment Date, Immunity, and Chemicals

You should check the treatment date and the chemicals used in the process. When you know the exact pesticides that have been used, you can read recommendations provided by the WHO to determine the level of danger. If the information is accurate, you can make the right decision and either replace the floor completely or apply a certain coating on top. One thing to note is that the CSC plate data could be false due to the floor replacement.

Consult a Specialist

If you have doubts about the chemicals used, the best decision is to consult a specialist. In some cases, you may try contacting manufacturers of containers. Or, you can consult a Pelican Containers flooring expert who can help you make the most informed decision regarding your container.

Final Thoughts

Nowadays, shipping containers can be used for numerous purposes, such as storage, living, and more. There are many types of shipping container floors that you can choose depending on your needs and preferences. The most important thing is to choose safe materials if you or others plan to spend time inside a container.

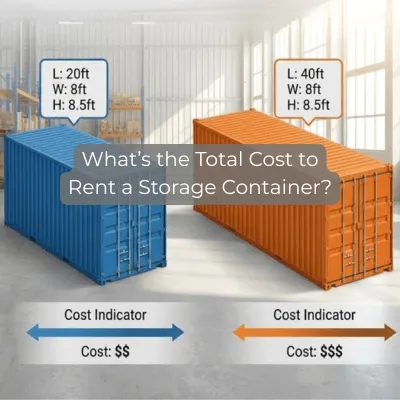

At Pelican Containers, we sell top-quality containers for individuals and businesses worldwide. Do you need 40ft high cube shipping containers? Or maybe 20ft standard containers? You can choose from our selection of used and new ones. Our specialists offer all the information you need and can help you select the best container with the right flooring.

Contact us and get a high-quality and safe container wherever you live!

6 Tips on How to Keep Your Storage Container in Great Condition

Used shipping containers are a much-preferred storage option. These robust boxes are easy to find and are much cheaper than the construction cost of a typical storage shed of the same size. However, just like everything else, shipping containers too need some maintenance to last for a lifetime.

Vanessa is a dedicated writer and content enthusiast at Pelican Containers. With a background in practical writing and a keen eye for clarity, she transforms complex container topics into easy-to-understand and useful content. Her passion lies in exploring the evolving world of container usage — from smart storage hacks to global logistics trends.

When she's not writing, Vanessa loves discovering creative shipping container projects or traveling to find new inspiration.

Explore thoughtful, informative, and accessible content with Vanessa!

Vanessa is a dedicated writer and content enthusiast at Pelican Containers. With a background in practical writing and a keen eye for clarity, she transforms complex container topics into easy-to-understand and useful content. Her passion lies in exploring the evolving world of container usage — from smart storage hacks to global logistics trends.

When she's not writing, Vanessa loves discovering creative shipping container projects or traveling to find new inspiration.

Explore thoughtful, informative, and accessible content with Vanessa!

FAQ

What materials should I use for the bottom of a shipping container?

The choice should depend on how a container will be used. If it is used for residential or office spaces, you can choose carpet tiles, vinyl planks, or imitation wood. If a container is used for transporting goods, the floor can be made of steel, aluminum, or plywood.

What is the thickness of a shipping container floor?

The thickness of the floor depends on the material. The standard thickness of the plywood floor of a container is about 1-⅛ inches.

How much weight can a shipping container floor hold?

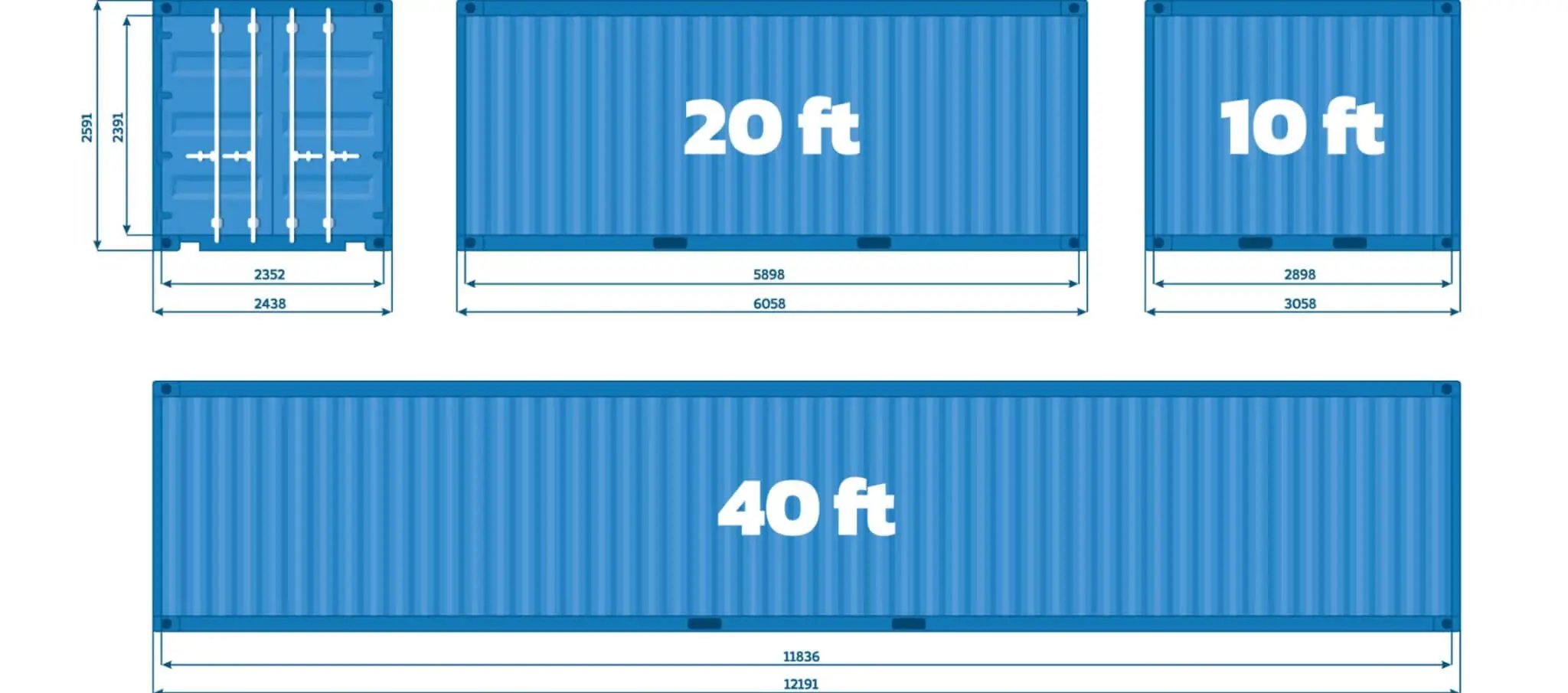

There are regulations regarding the maximum floor load in transportation containers. In the case of 20ft open top shipping containers, the maximum load on the floor per running meter is 4.5 tons, and for the 40ft containers, it is 3 tons per meter.