Intermodal Containers: All You Need to Know

The shipping industry would not exist without intermodal freight containers—they have long been essential in effectively moving commodities across great distances. While many different types of intermodal containers are available, they all work toward the same end: making transportation easier and cheaper. In this article, we will look at what an intermodal container is, how it works, its lifespan, available varieties, and much more.

Essential Guide to Understanding Intermodal Containers

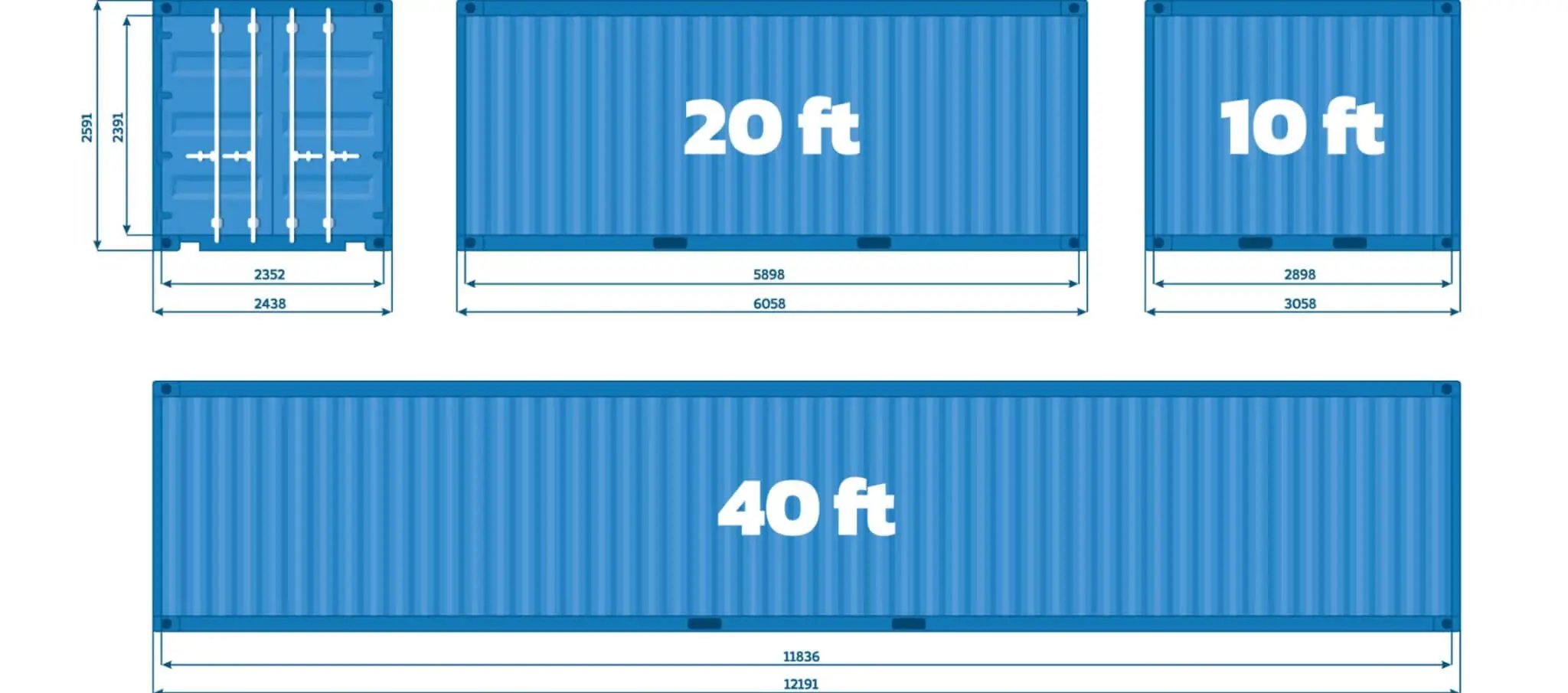

So, what is an intermodal container? Standardized cargo containers, commonly called “intermodal containers,” are designed to be loaded and unloaded using any of three different modes of transportation: trucks, trains, and ships. The standard container dimensions are usually 20ft x 8ft x 8ft 6in and 40ft x 8ft x 8ft 6in. This well-thought-out layout lessens the need for manual handling, reduces the likelihood of damage, and lowers transportation expenses.

In the 1950s, American businessman Malcom McLean revolutionized the transportation industry with the idea of intermodal freight containers. Thanks to this breakthrough, transport times and expenses were both reduced significantly, shipping exploded all across the world, and contemporary logistics were never the same.

The modern international economy could not function without intermodal transport containers. They make it easy to transport raw resources, intermediate commodities, and finished goods across oceans.

What is an ISO Shipping Container?

A universal or intermodal container is a sizable, standardized unit made to store and move cargo easily across a range of transportation channels, such as sea, rail, and road. When it comes to this context, global standardization—often referred to as the ISO shipping container standard—is all about:

- Maintaining structural integrity;

- Ensuring toughness against a wide range of weather conditions;

- Offering appropriate sizing and longevity for an intermodal load.

Types of Intermodal Containers

Different items and logistics situations call for specific types of intermodal containers:

- Standard dry containers: Widely used for general shipments and dry goods.

- Refrigerated containers (reefers): Feature a temperature control system for perishable goods like pharmaceuticals and produce.

- Open-top containers: Ideal for oversized cargo that cannot fit through the doors of standard containers.

- Flat rack containers: Used for massive or oddly shaped objects, such as heavy machinery.

- Tank containers: Designed specifically for carrying liquids, gases, and hazardous materials.

But how do these transport containers function in the shipping process? The intermodal shipping containers process is a well-oiled machine: goods are loaded into containers at their point of origin and sealed for the journey. Because of their consistent dimensions and specifications, intermodal containers are ideal for seamless transfer between ship, rail, and truck.

Usage in Major Industries

Intermodal containers are a linchpin in various global industries:

- Retail: These containers ensure that everything from electronics to clothing arrives intact and on time from factories to store shelves, often crossing oceans and land.

- Agriculture: Intermodal containers offer a regulated environment that keeps agricultural items, such as grains, animal feed, and fresh vegetables, safe and fresh throughout transportation.

- Automotive: Car parts and even whole vehicles are transported across continents using these containers. Specialized container sizes ensure that shipments remain secure from the assembly line to the market.

- Construction: Equipment and building materials are delivered to construction sites quickly, often in specialized high-cube containers designed for voluminous loads.

- Pharmaceutical and chemical: These sectors depend on intermodal containers as they can safely transport gases, liquids, and other potentially dangerous items in accordance with strict safety regulations.

These containers save on handling time and damage risk in all of the aforementioned businesses by enabling items to be transported without repackaging.

Intermodal Containers: Practical Knowledge and Applications

Beyond standard logistics, an intermodal shipping container is also used in:

- Disaster relief and humanitarian aid: In times of crisis, shipping containers may double as makeshift classrooms, hospitals, and command centers. Quick deployment in disaster zones is possible thanks to their modular nature.

- Aquaculture: In the seafood industry, an ISO shipping container provides controlled environments for fish farming and enables sustainable seafood production with reduced ecological impact.

- Data centers: Tech companies are implementing container-based data centers. These “data center in a box” solutions are perfect for increasing computing capacity without building new conventional facilities since they are scalable, quickly deployable, and cost-effective.

- Architecture: Vertical container farms, art galleries, and event venues are some of the other uses for repurposed intermodal containers. Additionally, some businesses follow the principles of the circular economy, which include reusing and recycling containers once they have served their transportation function.

Understanding Standard Container Dimensions & Capacity

For the safe transport of goods across modes of transportation, the International Maritime Organization (IMO) and other leading maritime bodies have established rigorous regulations, such as the International Convention for Safe Containers (CSC). The industry-wide standardization of standard container dimensions and functionalities is the goal of these rules.

Regarding standard container dimensions, a standard ISO shipping container measures 8 feet wide by 8 feet 6 inches high and can be 20 or 40 feet long. On the other hand, larger containers can be 9 feet wide by 10 feet tall and up to 53 feet long. [Check our guide on dimensions here].

The carrying capacity of these containers is denoted in TEU (Twenty-foot Equivalent Units). A TEU equates to the cargo volume that a standard 20-foot container, 8 feet in width, can transport.

Earning the ISO seal is a must for container shipping. Aside from coded information that identifies the transportation company, each intermodal shipping container bears an ISO certification stamp. Many different types of items can be transported using intermodal containers. Constructed from durable materials like COR-TEN steel or aluminum, they are well-suited to carry even refrigerated items.

There is one critical feature on a standard intermodal container: the cargo doors and standardized corner castings. This ease of use makes it possible to lock containers onto trucks and rail wagons, ensuring that they arrive at their destination without a hitch.

Intermodal Transport Efficiency

Intermodal shipping companies expertly manage the transfer of cargo between ports and railway yards to its final destination, significantly cutting down on crane usage, truck turnaround, and fuel costs. The cost-efficiency of carrying products in an ISO shipping container is a major factor in their popularity among enterprises.

These multipurpose containers can hold substantial intermodal loads. A 40-foot container has a Max Gross Mass of roughly 67,200 lbs (payload varies by tare weight), while a 20-foot container is similarly robust. The capacity to move a broad range of goods is further enhanced by rail transport, which can handle these heavy weights efficiently. The bigger 53-foot containers are perfect for major shipments, such as furniture and cars, across long distances since they offer significantly more volume than their 40-foot counterparts.

Intermodal transport is known for its safety, particularly when contrasted with more conventional techniques like breakbulk shipment. Made of steel, these containers safely move goods over great distances despite inclement weather like heat and rain. They successfully protect products from theft and water damage with their multi-layered metal or insulating constructions.

Vanessa is a dedicated writer and content enthusiast at Pelican Containers. With a background in practical writing and a keen eye for clarity, she transforms complex container topics into easy-to-understand and useful content. Her passion lies in exploring the evolving world of container usage — from smart storage hacks to global logistics trends.

When she's not writing, Vanessa loves discovering creative shipping container projects or traveling to find new inspiration.

Explore thoughtful, informative, and accessible content with Vanessa!

Vanessa is a dedicated writer and content enthusiast at Pelican Containers. With a background in practical writing and a keen eye for clarity, she transforms complex container topics into easy-to-understand and useful content. Her passion lies in exploring the evolving world of container usage — from smart storage hacks to global logistics trends.

When she's not writing, Vanessa loves discovering creative shipping container projects or traveling to find new inspiration.

Explore thoughtful, informative, and accessible content with Vanessa!

FAQ

What are intermodal containers and why are they important?

Intermodal containers are standardized transportation units that can be used on trucks, trains, and ships without requiring the goods inside to be unloaded and reloaded. They decrease expenses, expedite international logistics, and shorten processing times. These containers are essential to maintaining safe and effective supply chains globally, providing a universal solution for intermodal transport.

What are the main types of intermodal containers?

There are several key types of intermodal containers designed for specific cargo. These include standard dry containers for general goods, high cube containers offering extra height, refrigerated containers (reefers) for temperature-sensitive goods, and open-top containers for oversized items. Each ISO shipping container is customized to fulfill individual shipping demands safely.

What are the advantages of using refrigerated containers?

Refrigerated intermodal shipping containers, or reefers, are used for transporting perishable goods like food and pharmaceuticals. Their consistent temperature control guarantees that items stay fresh and undamaged upon arrival. No matter the distance, this capability maintains the quality of critical goods, eliminates waste, and avoids spoilage during intermodal transport.

How does intermodal transport benefit the logistics industry?

The goal of intermodal transport is to maximize efficiency and minimize expenses by combining the best features of individual transportation modes (rail, ship, and truck). Since it reduces carbon emissions and optimizes fuel consumption, this method also supports sustainable logistics while utilizing standardized intermodal containers for seamless movement.