How to Prevent Mold in Shipping Containers: The Ultimate Maintenance Guide

Shipping containers are the backbone of global trade and a top-tier choice for onsite storage. However, many users face a silent, expensive enemy: mold in shipping containers. Whether you are storing delicate textiles, food products, or paper documents, organic materials can quickly become a breeding ground for spores. Mildew in shipping containers doesn’t just smell bad—it can ruin the structural integrity of your cargo, rendering it unsellable and resulting in massive financial losses.

Are shipping containers airtight?

A common misconception is that these units are vacuum-sealed. While high-quality units are designed to be wind and water-tight (WWT) to withstand ocean spray, they are not strictly “airtight.” Microscopic moisture can still find its way in, or worse, be trapped inside at the time of loading.

Fortunately, shipping container mold prevention is a science that can be mastered. In this guide, we will dive into the mechanics of moisture in shipping container environments and show you how to protect your investment.

Why Do Shipping Containers Sweat? Understanding the Causes of Mold

To effectively prevent mold in storage containers, you must understand the phenomenon known as “Container Rain.” ### What is Container Rain? When the temperature inside a container drops below the dew point, the air can no longer hold its moisture. This causes water to condense on the ceiling and walls—literally “raining” down on your cargo. This cycle of shipping container condensation is the primary driver of mold growth. If you are struggling with this, see our specialized 7 steps for stopping shipping container condensation.

Common factors that trigger mold include:

- Contamination of Products: Mold spores are often already present on items before they are loaded. If the environment becomes humid, these spores activate.

- Hygroscopic Cargo (Wet Products): Items like wood, paper, or agricultural products hold “hidden” moisture. When sealed inside, this moisture evaporates and contributes to shipping container humidity.

- Wet Packing Materials: Cardboard boxes and wooden pallets are notorious for holding water. If they are damp during loading, they will release that moisture as the container heats up.

- Trapped Air: Excessive “dead air” in packaging can hold enough humidity to cause dampness during long transit or storage durations.

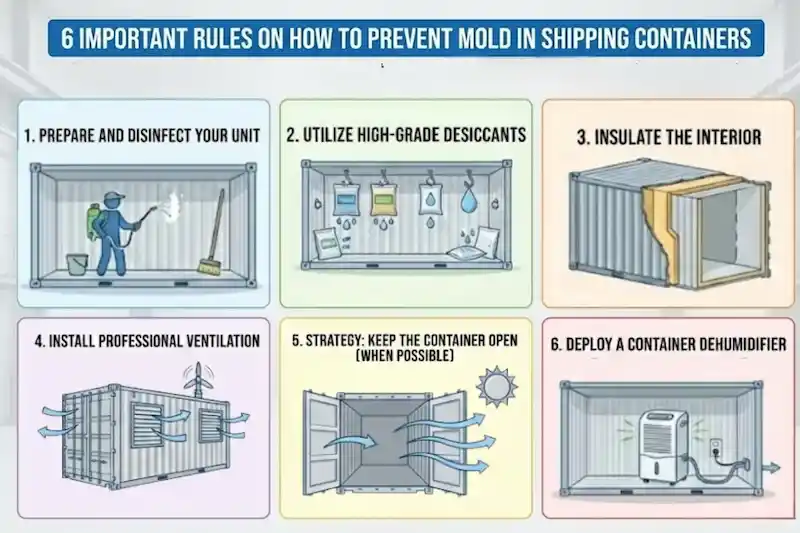

6 Important Rules on How to Prevent Mold in Shipping Containers

It is significantly more cost-effective to maintain shipping containers properly than to perform a clean moldy shipping container operation after the damage is done. Follow these structured steps to ensure your unit remains a mildew-resistant storage container.

1. Prepare and Disinfect Your Unit

Before loading, you must ensure the interior is a sterile environment.

- Step 1: Thoroughly clean the interior. You can hire professionals or do it yourself.

- Step 2: Use a vinegar solution or a specialized antimicrobial spray to kill existing spores.

- Step 3: Spray surfaces, let them sit for five minutes, and wipe clean with a dry cloth.

- Step 4: Ensure the container is 100% dry before introducing any inventory. A bowl of baking soda can help absorb residual scents and moisture.

2. Utilize High-Grade Desiccants

A shipping container desiccant acts as a sponge for the air. These are essential for long-term shipping container storage.

- Selection: Common agents include silica gel, calcium chloride, and charcoal.

- Placement: Hang desiccant bags from the internal lashing rings or place them on the walls and floor.

- Maintenance: Check your desiccants periodically. Once they reach saturation, they must be replaced to remain effective.

3. Insulate the Interior

To insulate shipping container walls is to break the cycle of condensation. Insulation keeps the interior temperature stable, preventing the air from reaching the dew point.

- Materials: For the best results, review the best options for insulating your shipping containers.

- Benefit: By minimizing the temperature gap between the inside and outside, you virtually eliminate shipping container condensation.

4. Install Professional Shipping Container Ventilation

Airflow is the enemy of mold. Shipping container ventilation grilles allow humid air to escape before it can condense.

- Function: Vents allow the unit to “breathe,” equalizing internal and external temperatures.

- Strategy: Learn the right way to ventilate a shipping container to facilitate cross-ventilation.

5. Strategy: Keep the Container Open (When Possible)

If your container is being used for static storage in a secure area, keeping the doors or hatches open during dry, sunny days provides natural airflow. This simple step helps prevent mold in storage containers by allowing any trapped moisture to evaporate naturally.

6. Deploy a Container Dehumidifier

For high-value cargo or climate-control shipping container setups, a container dehumidifier is the gold standard.

- Requirement: This requires a power source (via a generator or shore power).

- Operation: Modern units can be plumbed with a hose to the exterior so they can run continuously without needing to be manually emptied.

Final Thoughts

Mold and mildew can turn a valuable asset into a liability overnight. By understanding the relationship between temperature and shipping container humidity, you can take proactive steps to safeguard your goods.

If you’re looking to buy a shipping container, contact us! We offer new and used containers of all sizes, maintained to the highest industry standards.

6 Tips to Keep Your Storage Container in Top Condition

Used shipping containers are a premier choice for high-durability storage. These robust steel boxes are readily available and significantly more cost-effective than building a traditional storage shed of the same dimensions. However, to ensure your container lasts a lifetime, consistent maintenance is essential. Watch these 6 expert tips to protect your investment.

Vanessa is a dedicated writer and content enthusiast at Pelican Containers. With a background in practical writing and a keen eye for clarity, she transforms complex container topics into easy-to-understand and useful content. Her passion lies in exploring the evolving world of container usage — from smart storage hacks to global logistics trends.

When she's not writing, Vanessa loves discovering creative shipping container projects or traveling to find new inspiration.

Explore thoughtful, informative, and accessible content with Vanessa!

Vanessa is a dedicated writer and content enthusiast at Pelican Containers. With a background in practical writing and a keen eye for clarity, she transforms complex container topics into easy-to-understand and useful content. Her passion lies in exploring the evolving world of container usage — from smart storage hacks to global logistics trends.

When she's not writing, Vanessa loves discovering creative shipping container projects or traveling to find new inspiration.

Explore thoughtful, informative, and accessible content with Vanessa!

FAQ

How do I prevent mold in storage containers

Maintaining an optimal humidity level is key. Use a combination of shipping container desiccant packs, proper insulated shipping container techniques, and active shipping container ventilation to keep air moving and dry.

Can I use a shipping container after mold?

Yes. You can clean moldy shipping container surfaces using vinegar or industrial biocides. Once disinfected and thoroughly dried, the container is safe for use. If your unit has structural issues as well, check our guide on how to repair common types of damage.

What causes mold in the container?

Mold is caused by the presence of spores combined with high humidity and stagnant air. When “Container Rain” occurs due to temperature fluctuations, it provides the perfect moisture for these spores to thrive.