What is a Container Depot? A Strategic Guide to Storage, Costs, and Logistics

In the high-stakes world of maritime logistics, an empty container is often viewed as a liability. However, where that container sits and how it is maintained can determine the profitability of your supply chain. This facility is the container depot.

Far more than a simple parking lot for steel boxes, the modern container depot is a critical buffer in the global supply chain, facilitating container trading, essential maintenance, and strategic container repositioning. Whether you are a freight forwarder, a leasing company, or a shipper, understanding the commercial mechanics of these facilities is essential for mitigating Demurrage & Detention (D&D) costs and optimizing asset turnaround.

In this article:

- Defining the Container Depot: More Than Storage

- Depot vs. Terminal: The Operational Differences

- Commercial Benefits: How Depots Cut Logistics Costs

- The Mechanics of Maintenance & Repair (M&R)

- Strategic Repositioning and Container Trading

- Future Trends: Automation and Sustainability

- FAQ: Commercial & Operational Insights

Defining the Container Depot: More Than Storage

A container depot is a specialized logistics facility designated for the storage, handling, and maintenance of empty shipping containers. While they are a vital node in the network, they are distinct from the high-velocity environment of a port terminal.

Depots act as the “lungs” of the supply chain. When trade imbalances occur—such as the surplus of empty containers in North America versus the shortage in Asia—depots absorb the excess inventory. They allow empty container depot operators to inspect, repair, and prepare units for their next voyage or for sale in the secondary market.

According to data from bodies like the Bureau International des Containers (BIC), efficient depot operations are crucial for maintaining the safety and certification of the global container fleet.

Depot vs. Terminal: The Operational Differences

For the uninitiated, the terms “depot” and “terminal” are often interchanged. Commercially, they serve vastly different functions.

- Container Terminal: Located at the port interface. Focuses on speed, vessel loading/unloading, and the movement of loaded cargo. Real estate here is premium-priced; storage is punitive.

- Container Depot: Can be port-proximate or inland. Focuses on empty container management, storage, repairs, and preparation.

Types of Depots: Location Matters

1. Port-Based Depots Located within or immediately adjacent to the port ecosystem. These facilities provide rapid access to terminals, ensuring quick turnaround times for vessels. However, land costs here are higher, which can translate to higher storage fees per TEU (Twenty-foot Equivalent Unit).

2. Inland Container Depots (ICDs) Also known as “dry ports,” these are located in the hinterland, connected by rail or road. ICDs are critical for container repositioning. By moving empties closer to inland exporters (e.g., agricultural centers), shippers avoid the cost of hauling empty boxes from the coast.

Expert Insight: Utilizing an ICD can significantly reduce drayage costs. Instead of a round-trip to the port, a trucker can terminate a box at a local depot, freeing up the chassis for the next move.

Commercial Benefits: How Depots Cut Logistics Costs

In logistics, efficiency equates to margin. Depot services offer specific mechanisms to save money on container storage and trading operations.

- Mitigating Demurrage and Detention (D&D): Storing a container at a port terminal beyond the free time is financially disastrous. Moving containers to a private off-dock depot stops the clock on port storage charges, offering a lower daily rate (per TEU/day).

- Flexible Capacity: Unlike fixed warehousing, container depots offer elastic capacity. During peak seasons or supply chain bottlenecks (as seen in recent years), depots provide the surge capacity needed to avoid clogging your own distribution centers.

- Inventory Control: Advanced depots use Gate Operating Systems (GOS) to provide real-time visibility. Knowing exactly which units are “food grade,” “cargo worthy,” or “damaged” prevents wasted trips and ensures the right box is released for the right cargo.

The Mechanics of Maintenance & Repair (M&R)

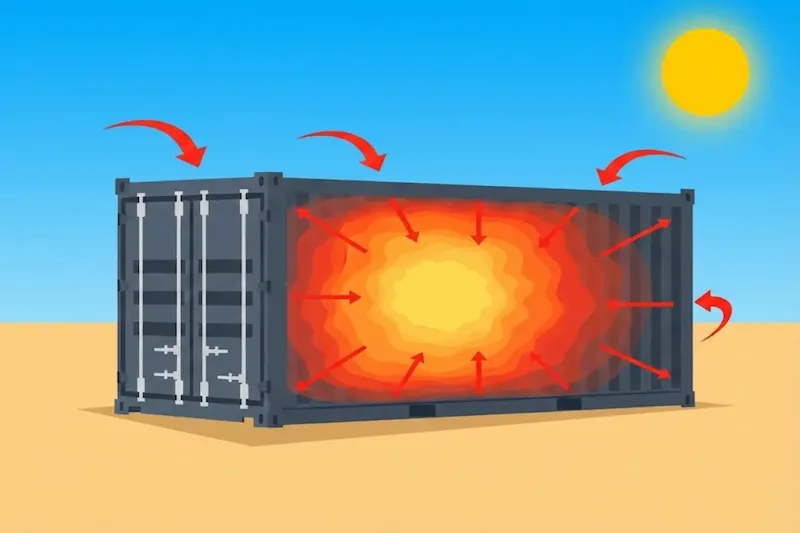

A container is only an asset if it is sound. Because containers spend their lives in harsh marine environments, depot services must include rigorous Maintenance & Repair (M&R) capabilities.

When a container enters a depot (Gate-In), it undergoes a survey. This is not a cursory glance; it is a liability transfer point.

The Survey Process

- On-Hire Survey: Conducted before a lessee takes a container. Ensures the unit meets the lease agreement standards.

- Off-Hire Survey: Conducted when a container is returned. The depot assesses if damage is “wear and tear” (owner’s account) or “improper handling” (user’s account).

Common Depot Repairs

Depots must adhere to standards set by the Institute of International Container Lessors (IICL) or the International Maritime Organization (IMO) CSC safety conventions. Common billable services include:

- CSC Inspections: Verifying the structural integrity for safe transport.

- Patching: Repairing holes or corrosion in the Corten steel panels.

- Flooring: Sanding or replacing plywood sections to ensure a flat surface for forklifts.

- Door Gear: Straightening locking bars and replacing rubber seals to ensure watertight integrity.

For a deeper understanding of the assets being repaired, you can refer to our guide on Standard Shipping Container Dimensions.

Strategic Repositioning and Container Trading

Depots are the marketplace for container trading. When shipping lines retire assets or when leasing companies sell off inventory, the transaction physically happens at the depot.

The Hub of Container Trading

Buyers looking for used containers—whether for one-way shipping (SOC) or static storage—rely on depots to categorize stock. A depot will segregate units into:

- New / One-Trip: Pristine condition.

- IICL/Cargo Worthy: Suitable for international transport.

- Wind & Watertight (WWT): Suitable for domestic static storage.

If you are in the market to purchase, understanding these grades is vital. (See: Container Specification 101).

Container Repositioning

Shipping lines lose billions annually moving empty air. Container repositioning strategies rely on depots to triangulate moves. A depot in Chicago might release a container to an exporter going to Rotterdam, effectively moving the asset back to a deficit area while generating revenue.

Future Trends in Container Depot Services

The depot sector is maturing from manual yards to tech-enabled logistics hubs.

- Automated Gates: Using Optical Character Recognition (OCR) to automatically log container numbers and seal integrity upon entry, reducing truck queues.

- Digital Twins & AI: Creating digital replicas of container stacks to optimize “shuffling” (moves required to get to a specific box), thereby reducing fuel consumption and lift costs.

- Sustainability: Leading depots are switching to electric reach stackers and solar-powered repair bays to lower Scope 1 and 2 emissions, aligning with the wider decarbonization goals of the International Chamber of Shipping (ICS).

Vanessa is a dedicated writer and content enthusiast at Pelican Containers. With a background in practical writing and a keen eye for clarity, she transforms complex container topics into easy-to-understand and useful content. Her passion lies in exploring the evolving world of container usage — from smart storage hacks to global logistics trends.

When she's not writing, Vanessa loves discovering creative shipping container projects or traveling to find new inspiration.

Explore thoughtful, informative, and accessible content with Vanessa!

Vanessa is a dedicated writer and content enthusiast at Pelican Containers. With a background in practical writing and a keen eye for clarity, she transforms complex container topics into easy-to-understand and useful content. Her passion lies in exploring the evolving world of container usage — from smart storage hacks to global logistics trends.

When she's not writing, Vanessa loves discovering creative shipping container projects or traveling to find new inspiration.

Explore thoughtful, informative, and accessible content with Vanessa!

FAQ

What is the difference between a container depot and a container terminal?

A terminal is a port facility focused on loading and unloading vessels. A container depot is a storage and maintenance facility (often inland or off-dock) used to store empty containers, conduct repairs, and facilitate container trading. Storage costs are significantly lower at a depot than at a terminal.

How are depot storage charges calculated?

Depot charges are typically structured around a “Gate-In/Gate-Out” (handling) fee plus a daily storage rate per TEU (Twenty-foot Equivalent Unit). Long-term storage agreements can often be negotiated at a lower flat rate compared to spot rates.

What should I look for in a depot service agreement?

Look for transparency in M&R (Maintenance and Repair) tariffs. Ensure the depot adheres to IICL repair standards to avoid overpaying for unnecessary repairs. Also, check their “turn time”—how quickly they can gate out a truck to avoid delays for your hauliers.

Can I buy a container directly from a depot?

Typically, depots hold stock on behalf of owners (leasing companies or shipping lines). However, trading companies (like Pelican Containers) utilize these depots to release stock to buyers. You can browse available inventory and buy a shipping container through verified trading partners who hold stock at these locations.